Individual customized solutions

Testing, measurement and automation tasks usually require specific, custom-made hardware solutions. Delphin's many years of experience in developing custom systems for specific sectors or applications enables them to offer users customized systems in 19“-racks and/or instrument cabinets. This means each 19“-system and instrument cabinet is designed according to customer needs and technical requirements.

Alongside the Delphin components intended as measurement and control units for cabinets, third-party and external equipment may also be integrated into the system.

Product highlights

- Single-sourced customized systems including hardware design

- Professional layout from mounting through to front panels

- Customized connection technology

- Choice of plug or clamp technology for sensor and actuator connection

- Expert engineering services for production of customized system

- Customer approval of design and plans prior to system delivery

- Compliance to all safety standards, e. g. DIN VDE 0100, 0701, 0702

- Full function testing

Versions

Measuring systems according to your requirements

Delphin offers customized systems as both 19“-systems and instrument cabinets. Any requirement can be met from compact systems through to multiple linked cabinet installations.

19“-rack systems

Different products are used for 19“-rack systems. 19“-rack systems are generally delivered as 3 HE, 4 HE, or 6 HE, depending on the required connection capacity. Delphin deliver customized 19"-rack systems also to customers with special equipment or software requirements.

Cabinets

Delphin can deliver cabinets as small compact systems, as wall-mounted installations, and as multiple linked systems on bases at heights of 2000 or 2200 mm. Depending on user requirements, the signals and input/outputs can be wired as series terminals or as plug-in / integrated connectors, e. g. to a front panel.

Connector panel

Connector panels mounted directly at the test sample site have a proven record within test engineering and test stand systems. Because Expert or Message devices are usually directly installed at the connector panel, the panels represent a fast path from sensor to data acquisition and control systems. Communication to a PC or centralized test stand cabinet can then take place via network systems. Cabling is minimized and users get a better overview of the test stand.

Connector technology

Connector technology is central for both cabinets and 19“-rack systems. Delphin can provide systems for any clamp, plug or integrated connector required. The connector technology used depends on user requirements, e. g. fixed or detachable wiring. Sensor and actuator connectors can be

- Series terminals/screw terminals

- Double terminals

- Spring terminals

- Plug-in screw and spring terminals

- Feed-through screw terminals

- 4mm laboratory connectors, also as safety lab plugs

- Lemo connectors (extensively used in the chemical sectors)

- Thermominiature connectors irrespective of thermocouple type

- BNC jacks

- Multi-pole circular connector

- Other connector technology

When required, Delphin can also integrate additional components such as an ICP-supply and power adapters. The connector technology is mounted to an engraved front panel. Connector identification is then still possible even after years of usage.

Function testing and safety

Each 19" rack or cabinet system of course complies to all relevant safety standards. A full earthing system is also present.

Documentation

Terminal layouts and connector and circuit diagrams are included with any new cabinet wiring installation. The required documentation is developed with the system and is included in delivery.

Functions

Special applications

Delphin's Message and Expert hardware form the basis for the 19“-rack and cabinet systems. These are equipped with the analog and digital input / outputs required by the user. All Message and Expert device functions are also available for 19"-rack and cabinet systems.

Analog inputs

The universal inputs on Message and Expert devices are wired as plug-in connectors or connector sockets. Signals can be measured directly and without the need for measurement transducers:

- Voltage signals

- Current signals 0/4 .. 20 mA

- Thermocouples (type K, E, N, L, J, S, U, R, T, B, C)

- Resistance thermometer (Pt100/Pt1000)

Delphin can integrate additional components, such as an ICP-supply and power adapters, into housings or cabinet systems when required.

Resistance measurement

Resistance measurement of up to 10 kOhm is possible as standard. Connection at the universal inputs using 4-wire technology. There is also an option for a resistance measurement set up for measuring currents with an ampere. This enables high-precision measurement of the smallest resistances, e. g. contact resistances. Alongside the Delphin measurement and control units in the cabinets, there are often also third-party and external equipment integrated into the system. This is especially the case for test stands.

- Contactors and relays

- Voltage regulation

- Variable transformers

- DC power units

- Power measuring units

- Resistance measurement units

- Frequency converters

Digital outputs/switch outputs

Digital outputs / switch outputs are directly wired as clamps or plugs. The standard set up for switch outputs is as passive DC contacts with currents of up to 50 VDC and a permitted continuous current of 2.5 A. When required by users, relays and contactors may also be installed that can be directly controlled by the switch outputs.

Digital inputs/status inputs/frequency inputs

Each digital input can be assigned 2 clamps or plugs. The standard digital input set up is passive with a high-level of between 3.5 V .. 90 VDC. Digital inputs can also be directly set up as 24 VDC contact inputs with a wired auxiliary supply of 24 V. This enables, for example, the acquisition of auxiliary contacts on relays.

Analog outputs

Each analog output is assigned 2 clamps or plugs. Each channel can be used as a 0/4 ... 20 mA signal. Additional components installed within the cabinets, e. g. variable transformers or frequency converters, can be directly operated.

Hardware

The following measuring and testing devices can be installed

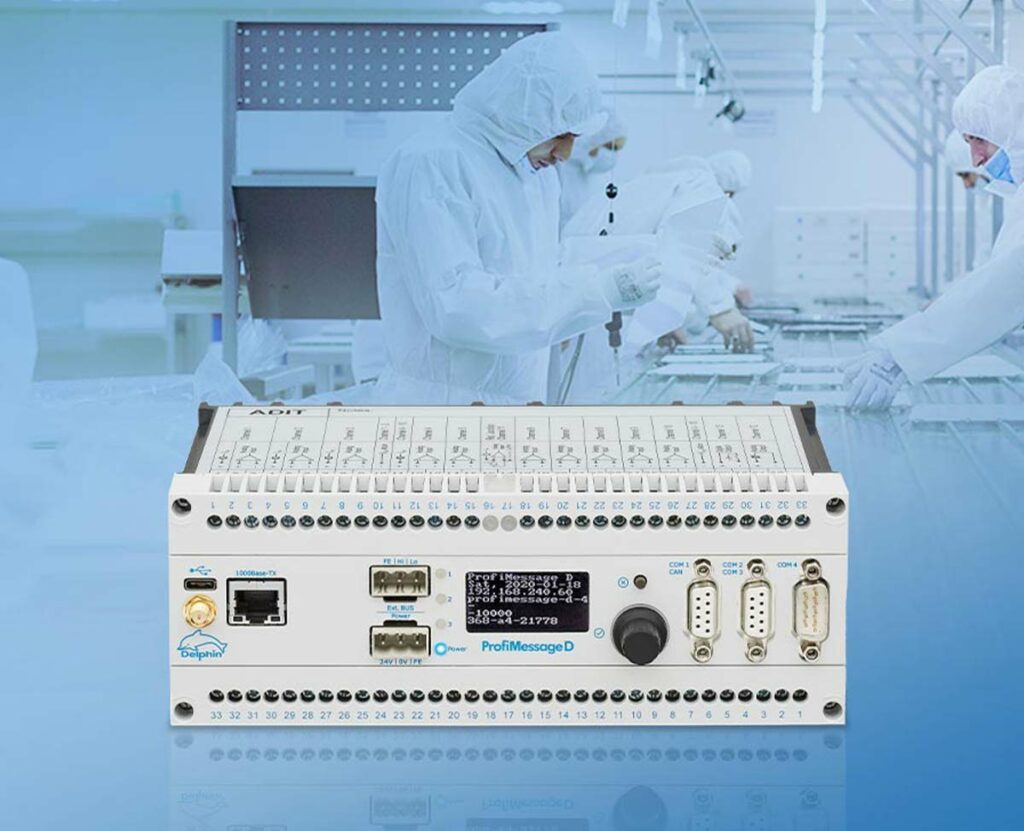

Modular measuring, monitoring and automation in one device.

The ProfiMessage D device is a state-of-the-art data logger system that has been specially developed for industrial data acquisition and analysis. It offers a wide range of functions such as the recording and storage of measurement data, monitoring of process parameters and alarms in the event of deviations.

To the product

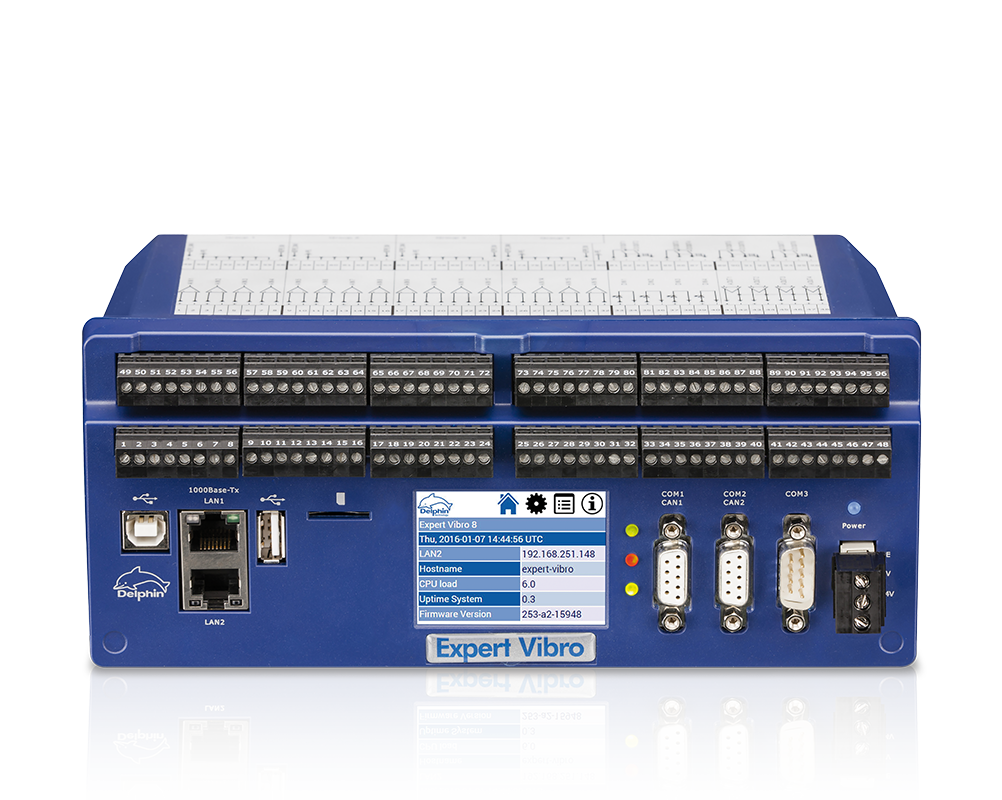

State-of-the-art processor technology and extreme precision for vibration measurement.

The Expert Vibro device is a powerful vibration analysis device that has been specially developed for monitoring and analyzing machine and system conditions. It enables vibration data to be recorded and evaluated in order to detect potential problems or signs of wear at an early stage.

To the product

Intelligent data recorder for synchronous recording of transient and periodic events.

The Expert Transient device enables the recording and evaluation of transient signals over a certain period of time and provides important information for the optimization of processes and systems. The device is characterized by its high accuracy, fast sampling rate and simple operation.

To the product

Precisely record, autonomously store, automatically transmit and evaluate measured values.

The FPGA-based Expert Logger device is particularly powerful and enables the processing of up to 46 analogue input channels, both at low and high sampling rates. Measured values can be precisely recorded, autonomously stored and automatically transferred to the internet or PC via USB, LAN or WLAN and evaluated.

To the product

Compact and flexible measurement data laboratory with precision measurement technology.

The LoggitoLab device is ideal for use in laboratory environments, research projects, quality control and other applications where precise data acquisition and analysis is required. It offers a reliable and user-friendly solution for monitoring and recording measurement data.

To the product

Flexible, scalable and expandable solution for seamless data acquisition and monitoring

The Loggito device is a compact data logger system designed for the acquisition and recording of measurement data. It has a variety of analog and digital inputs to connect different sensors and signals. The device records the data with high accuracy and stores it on an internal memory or external storage media such as SD cards.

To the product

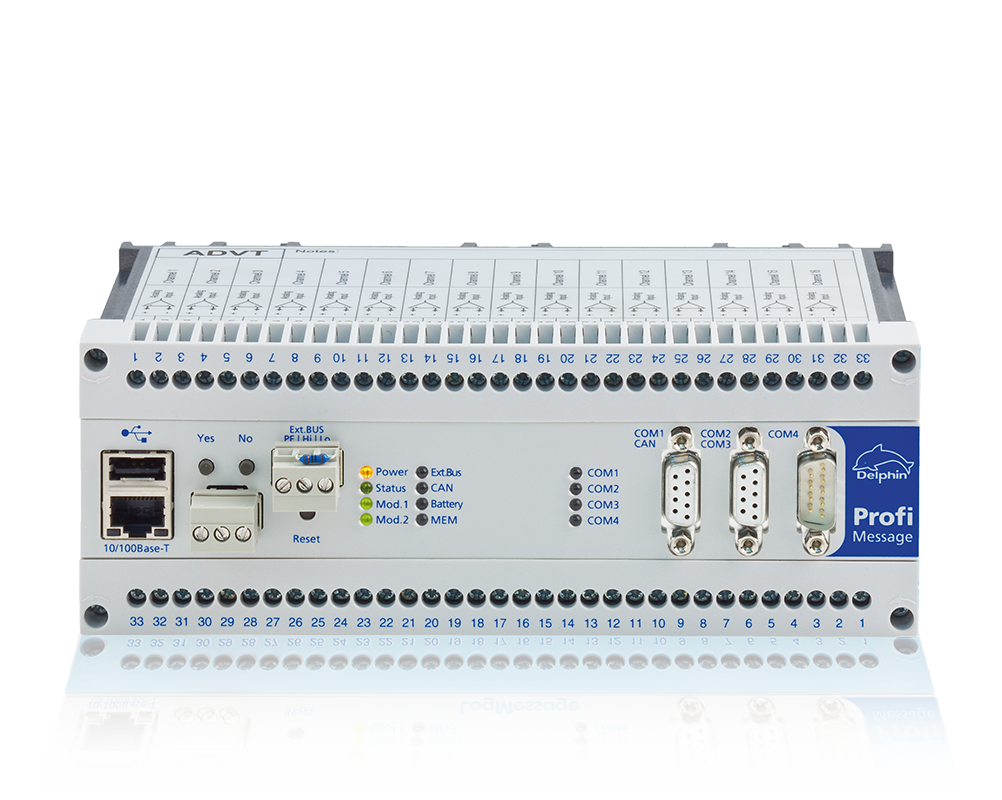

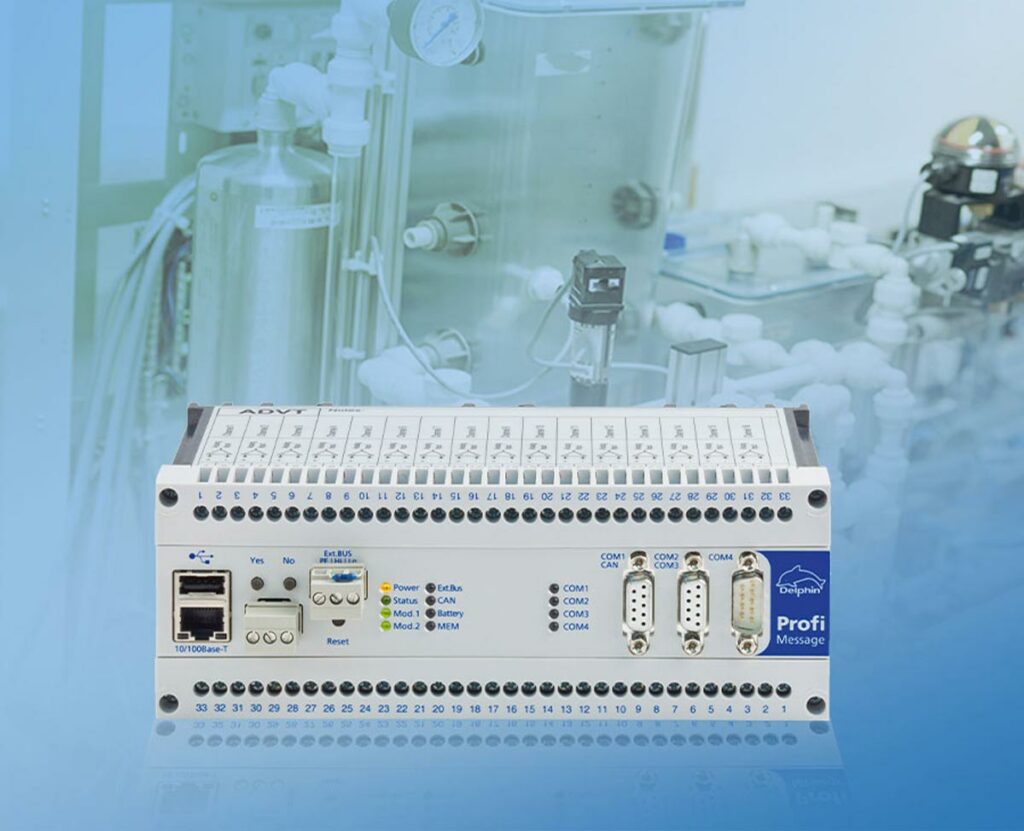

Modular system for use as a measuring, control and monitoring device.

The ProfiMessage devices are a modular, expandable and easy-to-use system for measurement data acquisition, monitoring and automation of machines, systems or test benches. ProfiMessage can be used wherever measured values need to be recorded quickly, precisely and electrically isolated, as well as intelligently pre-processed or monitored.

To the product

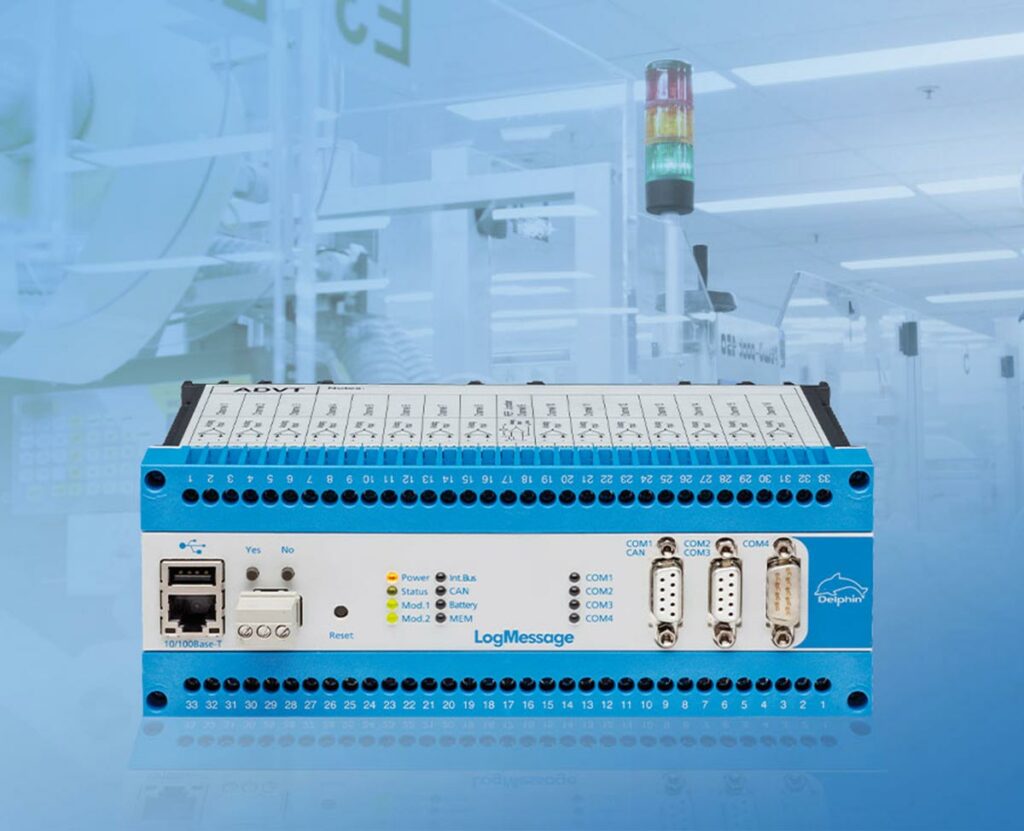

Test stand for measurements with potential using an internal data memory.

The LogMessage device is a powerful data logger system designed for the reliable acquisition and recording of measurement data. It offers a variety of analog and digital inputs to connect different sensors and signals. The device records the data with high accuracy and saves it to an internal memory or external storage media.

To the product