Energy data collection relieves energy-intensive companies

Energy data collection encompasses all measures for recording and analyzing energy consumption data in a company or household. By accurately recording energy consumption, potential savings can be identified and effective measures can be developed to increase energy efficiency. Energy data is usually recorded using smart meters or sensors that record consumption values in real time. This data is then evaluated and visualized using software solutions. Energy data logging can record not only electricity consumption, but also water, gas and heating energy consumption. By continuously recording and analyzing energy data, companies and households can reduce their energy costs and make a contribution to climate protection at the same time.

As part of the EEG regulation, it is not only particularly energy-intensive companies that decide to optimize their energy consumption. It is often necessary to record both process data and energy data simultaneously in order to identify correlations. With the scalable system from Delphin, this is exactly what is possible. The measurement technology devices can be installed decentrally on the processes and record analog values in parallel to control systems via mA interfaces. Alternatively, they can be connected via fieldbus. Meter readings are recorded via digital inputs. The ProfiMessage devices cumulate the counter pulses into time-synchronized power and work values. The data can then be clearly displayed parallel to the process values with ProfiSignal can be evaluated and printed out as reports.

Application highlights of process and energy data acquisition

- Development of a combined energy and process measurement network

- Stationary energy data acquisition

- Self-sufficient and secure energy data acquisition without a PC

- Simple analysis of the relationships between process characteristics and energy consumption

- Monitoring consumption and performance

Practical example of process and energy data acquisition

Combined energy and process data acquisition in titanium production

The production of titanium is a particularly energy-intensive process. At the same time, a particularly high product quality must be guaranteed. Titanium is a high-purity and very expensive material. A Delphin measuring network with message devices was set up to analyze and monitor energy consumption throughout the plant. The performance data is recorded in the Delphin system via a connection to existing power measurement units. Important process parameters are recorded in parallel. In this way, the manufacturer can simultaneously document the quality of its product in the manufacturing process and monitor its energy consumption and avoid overruns during expensive electricity tariff periods.

Typical areas of application

process and energy data acquisition

- Stationary energy data acquisition in steel and metal production

- Permanent process and energy monitoring

in printing and paper production - Recording of quality-relevant measured values and performance data

- Acquisition of energy data in the power plant

Hardware and software for your measurement and testing solution

Flexible, scalable and expandable solution for seamless data acquisition and monitoring

The Loggito device is a compact data logger system designed for the acquisition and recording of measurement data. It has a variety of analog and digital inputs to connect different sensors and signals. The device records the data with high accuracy and stores it on an internal memory or external storage media such as SD cards.

To the product

Data acquisition and analysis

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

Precisely record, autonomously store, automatically transmit and evaluate measured values.

The FPGA-based Expert Logger device is particularly powerful and enables the processing of up to 46 analogue input channels, both at low and high sampling rates. Measured values can be precisely recorded, autonomously stored and automatically transferred to the internet or PC via USB, LAN or WLAN and evaluated.

To the product

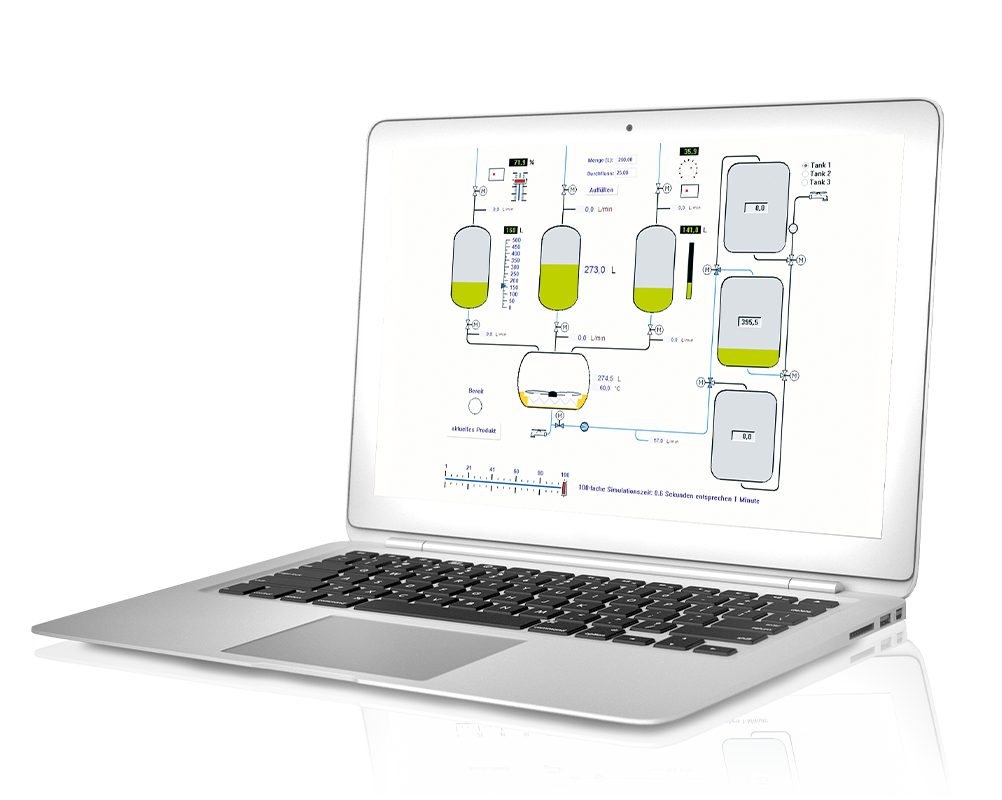

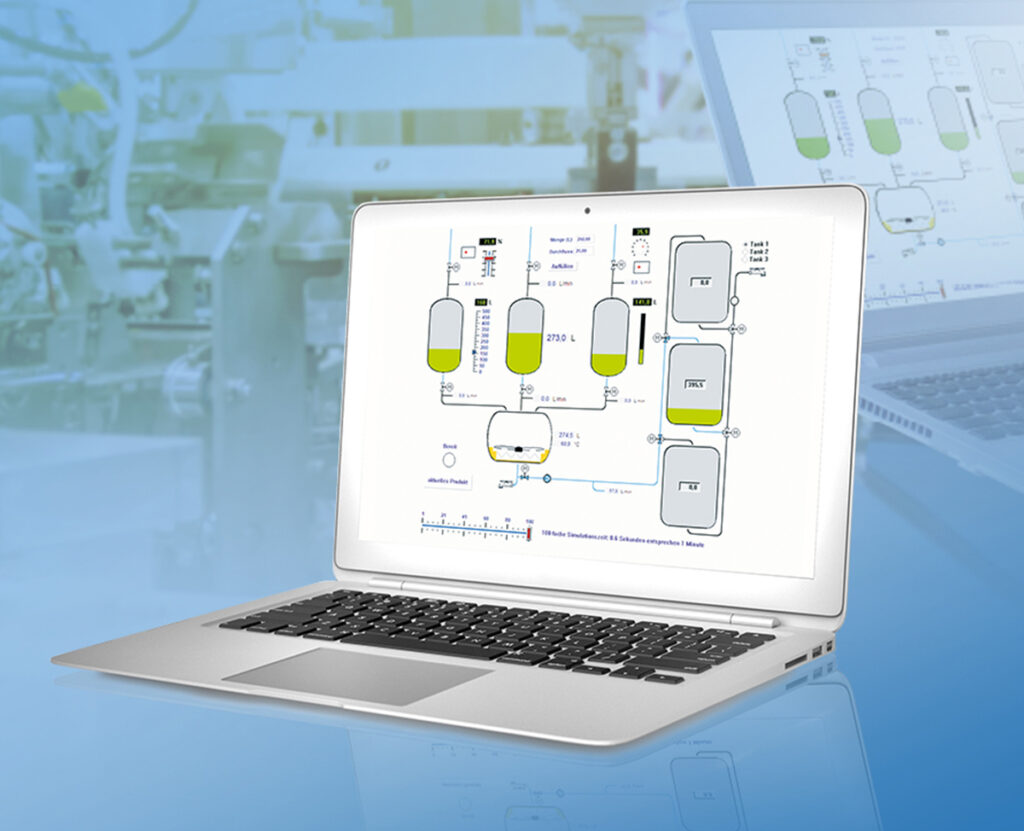

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

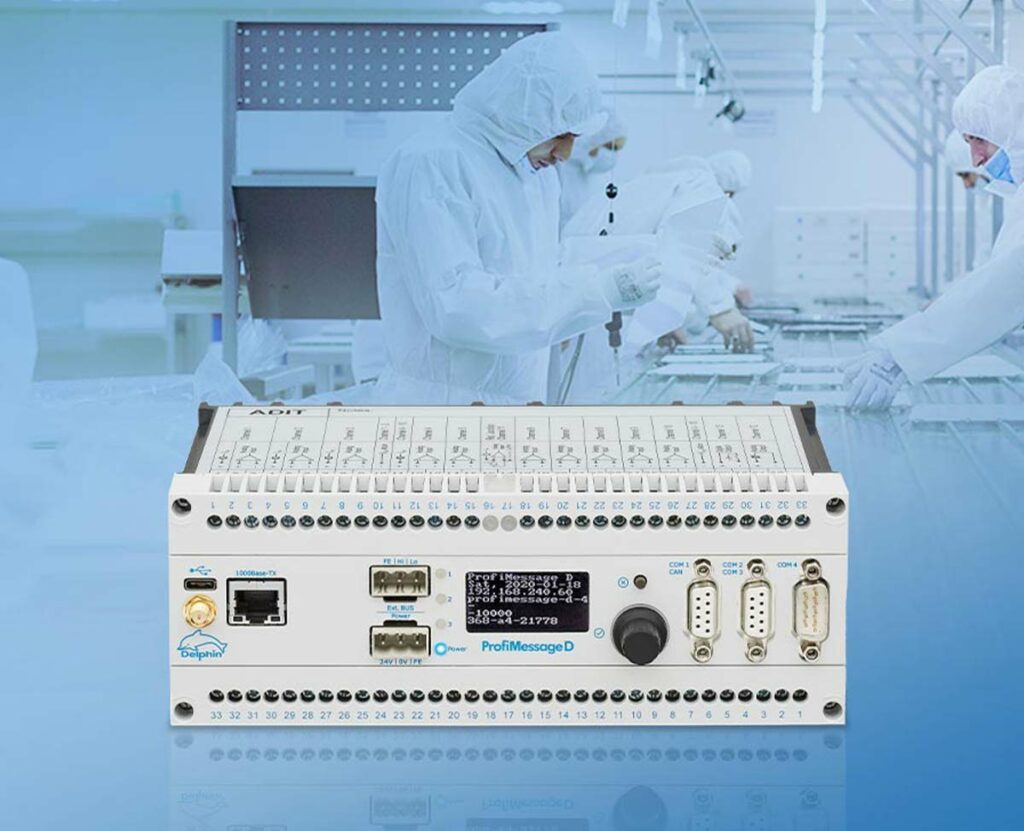

Modular measuring, monitoring and automation in one device.

The ProfiMessage D device is a state-of-the-art data logger system that has been specially developed for industrial data acquisition and analysis. It offers a wide range of functions such as the recording and storage of measurement data, monitoring of process parameters and alarms in the event of deviations.

To the product

Automate and control

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

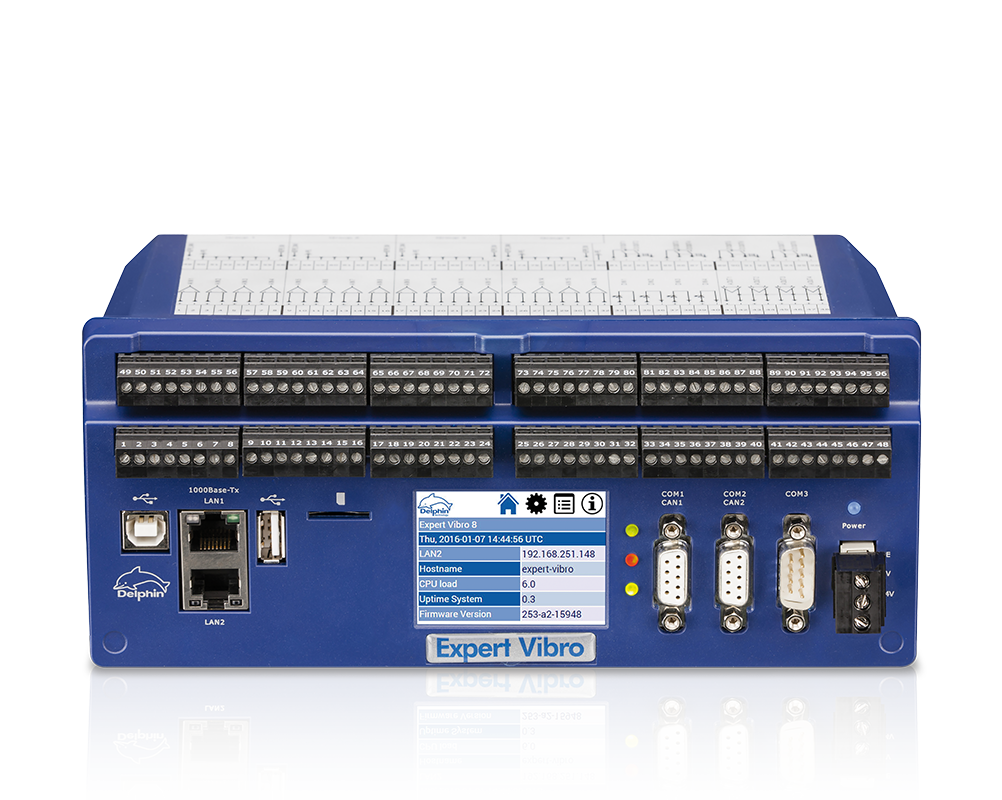

State-of-the-art processor technology and extreme precision for vibration measurement.

The Expert Vibro device is a powerful vibration analysis device that has been specially developed for monitoring and analyzing machine and system conditions. It enables vibration data to be recorded and evaluated in order to detect potential problems or signs of wear at an early stage.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

Intelligent data recorder for synchronous recording of transient and periodic events.

The Expert Transient device enables the recording and evaluation of transient signals over a certain period of time and provides important information for the optimization of processes and systems. The device is characterized by its high accuracy, fast sampling rate and simple operation.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

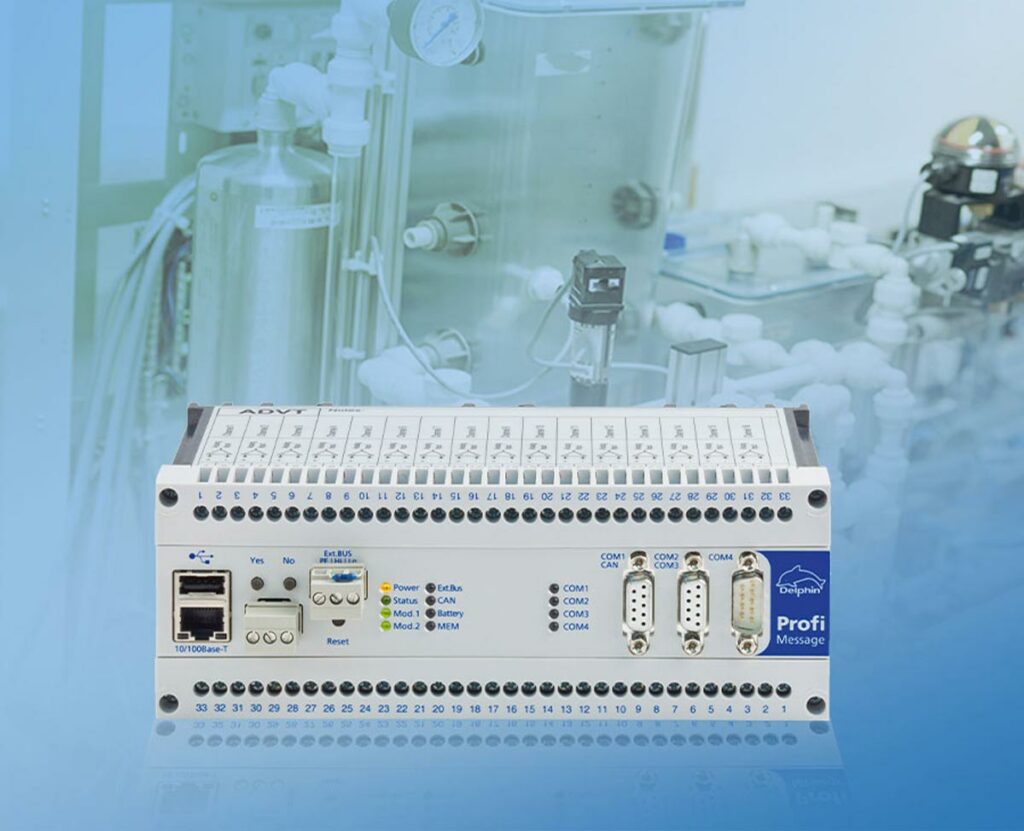

Modular system for use as a measuring, control and monitoring device.

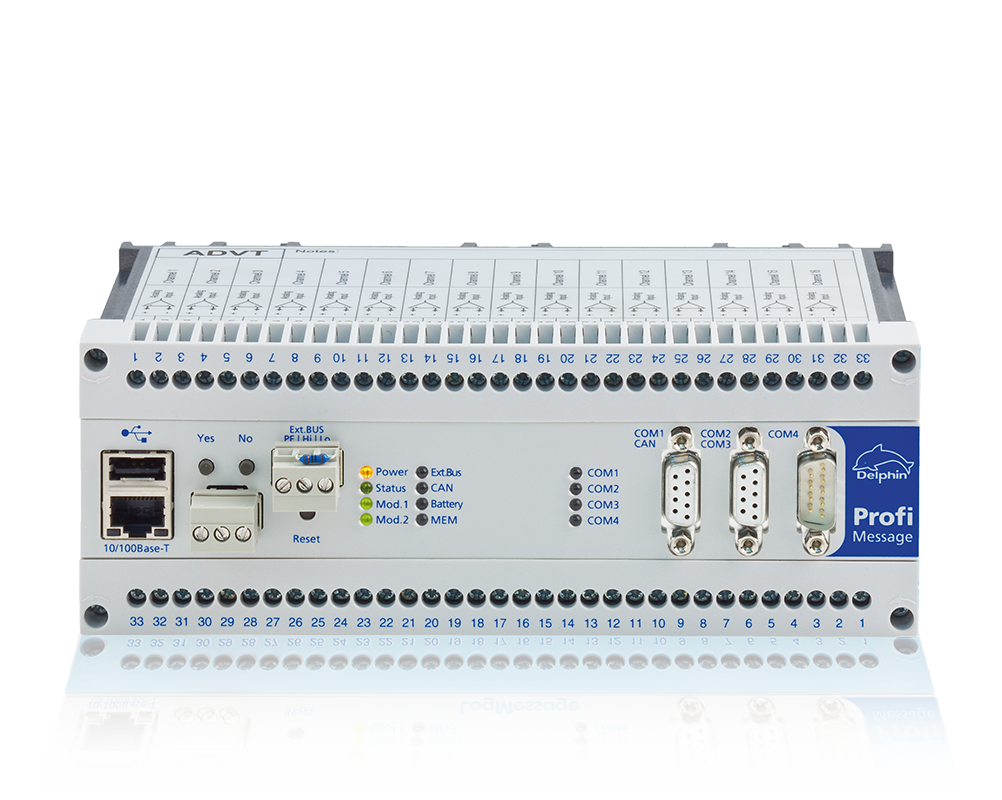

The ProfiMessage devices are a modular, expandable and easy-to-use system for measurement data acquisition, monitoring and automation of machines, systems or test benches. ProfiMessage can be used wherever measured values need to be recorded quickly, precisely and electrically isolated, as well as intelligently pre-processed or monitored.

To the product

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product

PC-supported data acquisition and test stand

The Expert Key device is a measuring and control device that can be used in various applications. It enables the acquisition and evaluation of measurement data as well as the control of processes. The device has various interfaces and can be connected to a wide range of sensors and actuators. It is often used in automation technology, mechanical engineering and research.

To the product

Compact and flexible measurement data laboratory with precision measurement technology.

The LoggitoLab device is ideal for use in laboratory environments, research projects, quality control and other applications where precise data acquisition and analysis is required. It offers a reliable and user-friendly solution for monitoring and recording measurement data.

To the product

Test stand for measurements with potential using an internal data memory.

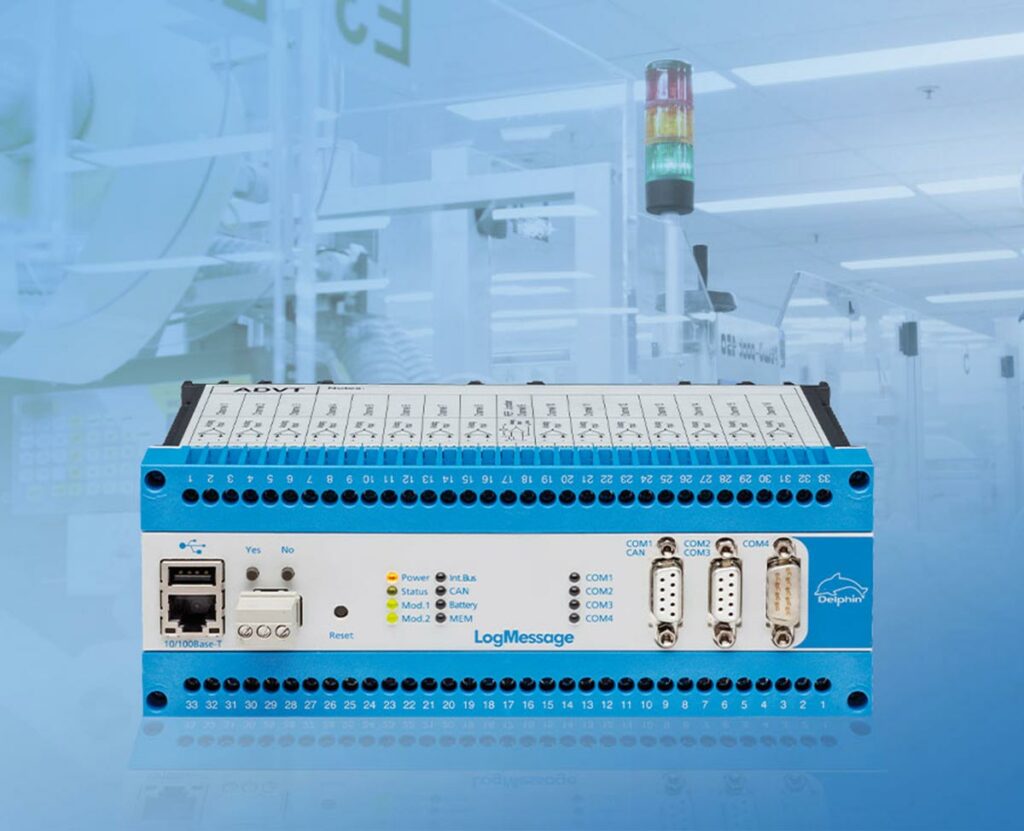

The LogMessage device is a powerful data logger system designed for the reliable acquisition and recording of measurement data. It offers a variety of analog and digital inputs to connect different sensors and signals. The device records the data with high accuracy and saves it to an internal memory or external storage media.

To the product