Synchronous detection and high accuracy with the transient recorder

The Expert Transient device is capable of synchronously acquiring and independently saving analog measurement data up to a sampling rate of 50 kHz per channel in combination with digital signals. Data storage is highly secure due to an option for parallel recording to internal and external storage media.

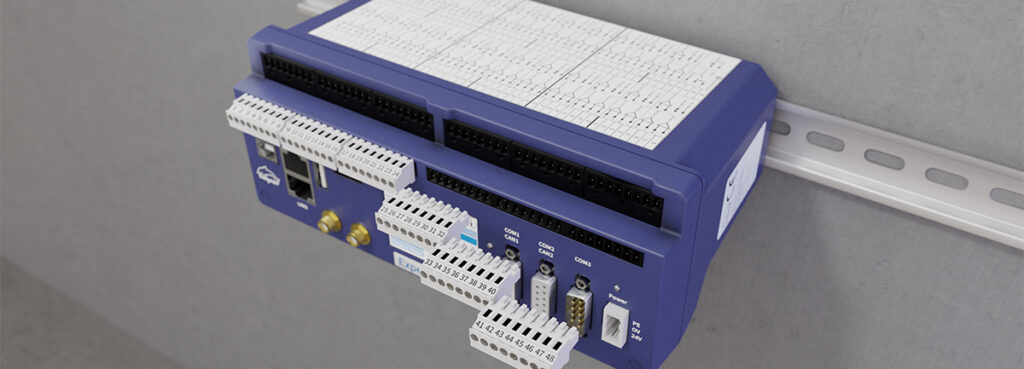

Expert Transient is equipped with 4, 8, 12 or 16 synchronous analog inputs and 4 digital inputs. The system can be extended to over 100 analog signals via a LAN interface with high-speed synchronization protocols. An extension for additional synchronous digital inputs is also possible.

ProfiSignal 20 Go software enables recorded signals to be portrayed live in y(t) diagrams. Even large volumes of historical data are easy to analyse using the ProfiSignal software. The device's internal storage can be accessed using ProfiSignal 20 Go and the data analysed offline. A signal sequence diagram is especially useful in providing an overview of the chronology of a malfunction event.

Product highlights

- Acquisition of transient and periodic signals

- Triggered and continuous acquisition modes

- Diverse range of analysis functions

- Optional with the ProfiSignal 20 Go analysis software

- Synchronously extendible with analog and digital inputs

- Independent, stand alone operation with long-term data storage capability

- Highly compact design

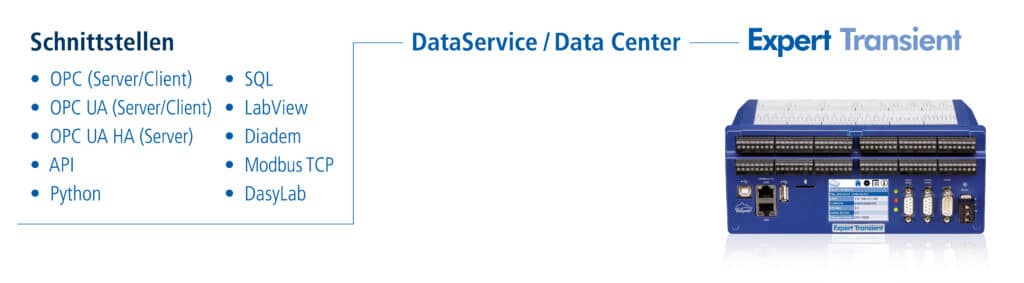

I/Os and interfaces

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

Solutions

- High-speed acquisition of analog or digital signals

- Fault diagnostics on machines, systems and test stand

- Evaluation of pressure pluses / surges

- High-speed process monitoring and controller optimisation

- Crash, detonation and explosion experiments

- Shock and vibration measurement

- Material research and environmental simulation

- Test stand and lab experiments

Functions

Universal inputs and outputs and secure monitoring

Sampling of analog and digital measurement data is performed fully synchronously. This enables precise identification of the sequence of events in a malfunction. Measurement data can be recorded either continuously or according to triggered events. Users are able to define triggers to also record pre and post event data. Expert Transient is available in two versions with 4, 8, 12 or 16 analog inputs as well as 4 digital inputs. The device can be extended by up to 100 analog or digital inputs.

For applications without a PC, measured values can be saved in the device's internal 12 GB data memory. Alternatively, parallel storage on an external NAS with a very large storage capacity is possible.

Expert Transient - detachable screw terminal illustration

Input signals

- Acquisition and analysis of high-speed, transient signals

- Triggered or continuous recording modes

- Synchronous acquisition of 4, 8, 12 or 16 galvanically isolated, analog signals

- Sampling rates of up to 50 kHz per channel

- High measurement precision (24-bit ADC)

- Four synchronous digital inputs

Trigger and monitoring functions

- User-defined, multiple, flexible trigger events

- User-define data storage partitions and triggers

- High-speed digital outputs for limit value violations

- Alarms via email or text message

Signal processing

- Online computation of effective and peak values

Data recording

- 12 GB self-sufficient, device-internal data memory

- Long-term data recording to NAS or SCSI drives

- Absolute-time synchronisation via GPS or NTP (optional)

- Automated FTP upload

- Internal time synchronisation via PTP

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

Versions

| Inputs / Outputs | Type 4 | Type 8 | Type 12 | Type 16 |

|---|---|---|---|---|

| Analog inputs (mV, mA) | 4 | 8 | 12 | 16 |

| Analog outputs (mV, mA) | 4 | 4 | 4 | 4 |

| Digital / Frequencies inputs | 4 | 4 | 4 | 4 |

| Digital outputs | 8 | 8 | 8 | 8 |

Software

Suitable software for Expert Transient

Data acquisition and analysis

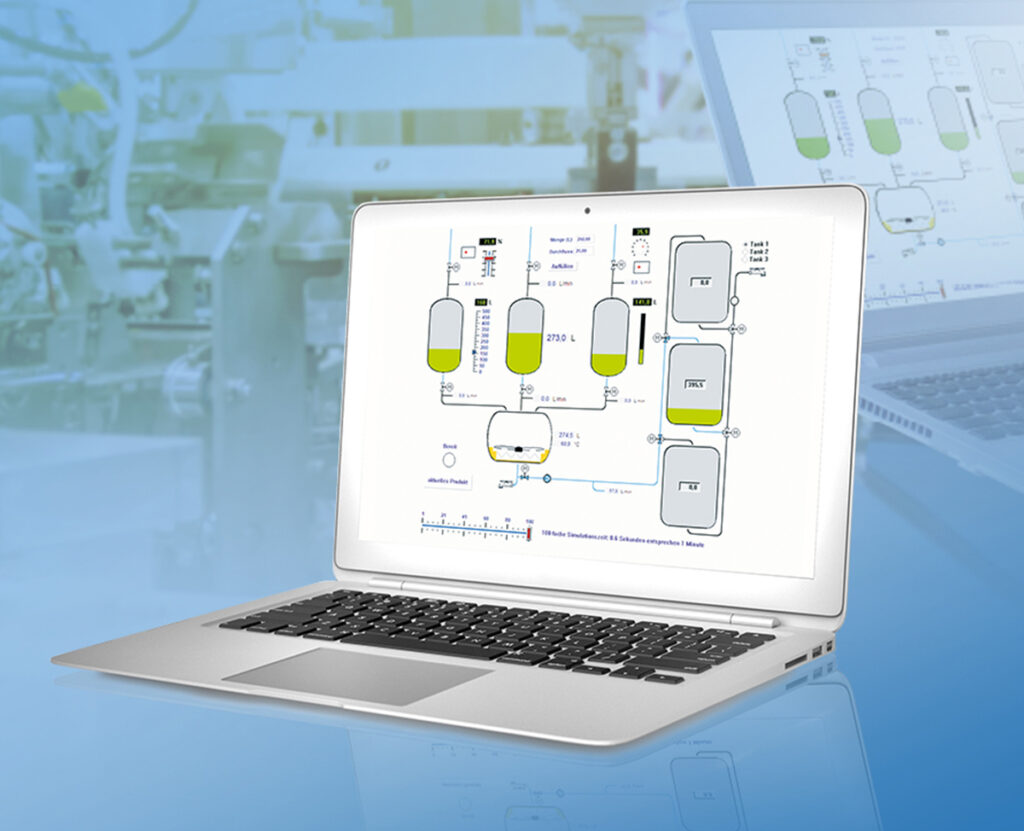

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

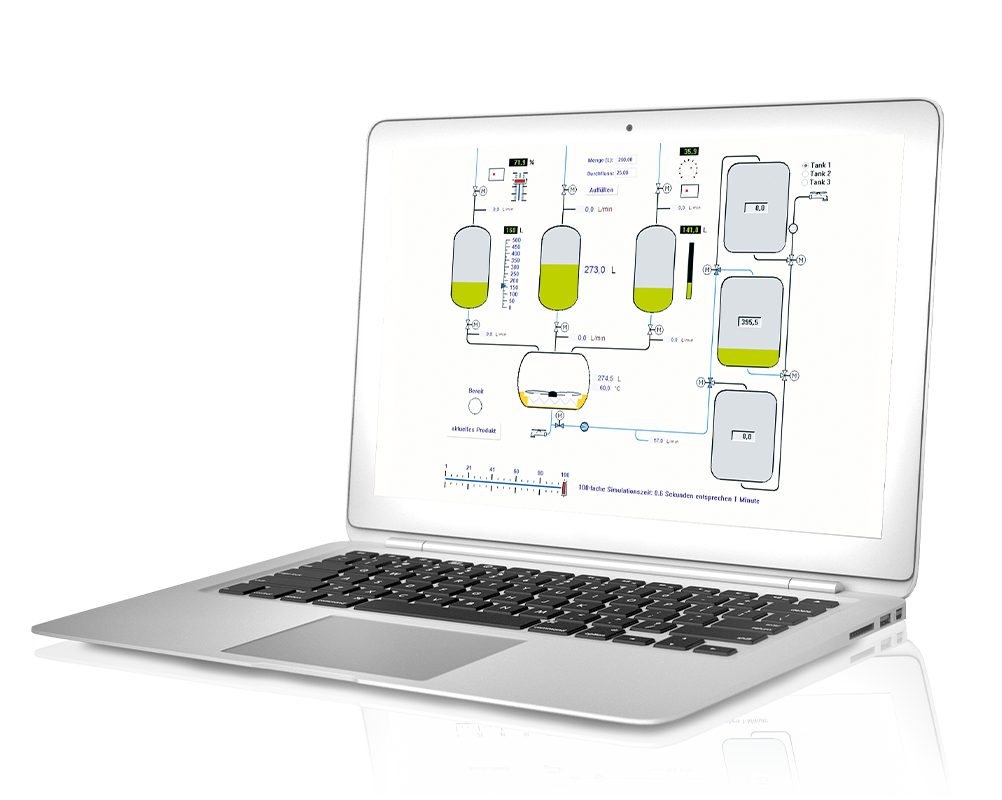

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

Automate and control

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product

Software channels as extended functions

Realise and execute monitoring and automation tasks easily

The Delphin measuring and testing devices have extended functions that are summarised under the term software channels. The online measurement data is calculated with the software channels and then used for visualisation, storage or control.

In this way, entire programme sequences can be configured very simply and intuitively with the regulation and control function. These then run autonomously without PC support. This is how you use your data logger effectively, also as a monitoring device or PLC replacement.

The software channels enable functions such as limit value monitoring, integration or online calculation and are configured very easily. This means that even users who are not experts in programming can easily implement their own monitoring tasks or balancing independently in the unit.

More informationSoftware interfaces