The multi-channel data logger for complex data acquisition

Do you need a highly flexible, compact and universal data logger for your most diverse measuring tasks? Then the Expert Logger is the optimal solution for your application.

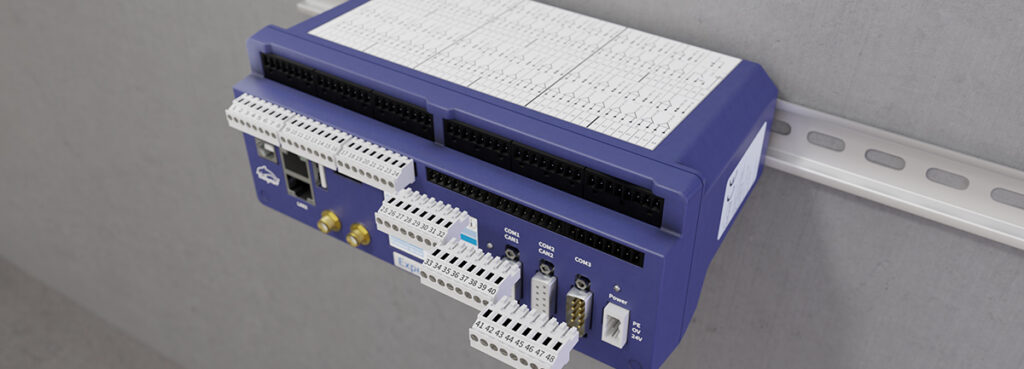

With just one device, it is possible to independently process up to 46 analog input channels for your application, both at low and high sampling rates. All channels are galvanically isolated from each other. Your measured values are precisely recorded, monitored, pre-processed and can be stored internally in the device memory. LAN or USB are available for transferring the measured values to a PC or server. Thanks to the integrated interfaces such as PROFIBUS, Modbus and OPC UA, an optimum connection to your existing infrastructure is always possible.

Product highlights

- Universal analog inputs (mV, mA, thermocouple, RTDs)

- SDI12 interfaces for environmental sensors

- Independent operation possible with batteries or rechargeables

- Minimal energy consumption via a sleep function

- 12 GB internal memory for up to 360 million measured values

- PUSH function to send measurement data to the internet

- LAN and USB interface to a PC or network

- Monitoring and data logging in a single device

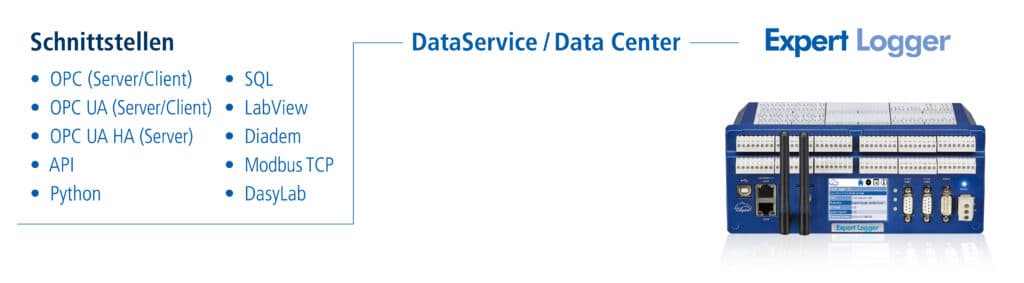

With an OPC UA interface

OPC UA is becoming an increasingly established protocol and when used with the Expert Logger devices, measurement acquisition, monitoring and test stand automation applications can be made ready for open data exchange data in accordance with Industry 4.0/Internet of Things.

Both OPC UA servers and clients have been integrated into the Expert Logger devices to enable fast, easy and barrier-free data exchange with sensors and sub-systems also supporting OPC UA.

Many products such as frequency converters, controllers and regulators have already fully integrated OPC UA. The opportunities provided by OPC UA have been identified within the measurement and sensor technology sector with several sensors and actuators now available with OPC UA interfaces.

In addition to OPC UA, Expert Logger devices are also equipped with PROFIBUS, ModBus, CAN-Bus and serial interfaces for sensor and field level connections.

I/Os and interfaces

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

Solutions

- Data logging

- Environmental measurement technology

- Product testing

- Measurement data diagnosis

- Laboratory data acquisition

- Trials and tests

- Energy optimization

Product video Expert Logger

Alternatively, you can watch the product video directly at the YouTube link.

Operation made easy

Detachable screw terminals

The sensor connection is made by means of plug-in screw terminals. The large connection diagram clearly shows the channel arrangement. Despite the high channel density, the clarity is maintained. Four connection terminals each can be configured as two differential inputs for measuring voltage, current or thermocouples or for measuring a Pt100(0) in four-wire circuit.

Expert Logger - detachable screw terminal illustration

Understandable configuration

Expert Logger can be configured conveniently from a PC using the configuration programme. The device configuration is retained in the Expert Logger even in a de-energised state. Configurations can be read out and saved on the PC. It is also possible to change the configuration offline without the Expert Logger device being connected. Offline configurations are then simply reloaded into the unit. With Expert Logger, configuration does not become the main task, but users can concentrate fully on the measuring task.

Intelligent signal processing

Signal processing by means of internal software channels simplifies the actual measuring task considerably. With the very flexible calculation channels, measured values can be further calculated and stored directly. Integrators calculate volumes or quantities directly from time-related measured values, such as mass or flow rates. Limit values can monitor measured values and be used to switch digital outputs or to automatically send e-mails. Complicated signal processing is also possible by means of impulse counters, time-step functions and operating hour counters. Mean values can be calculated and stored on a time-related or sliding basis. The software channels clearly distinguish Expert Logger from other data loggers and make them very popular with users.

Functions

Universal, communicative, reliable

Below is a list of the main features of Expert Logger. If you have any questions please contact us.

OPC UA interface

- Server/Client interface

- Suitable for Industry 4.0

- Open and barrier-free communication

Sensor connection

- Universal analog inputs (mV, mA, thermocouple, RTDs)

- Digital inputs and outputs

- Plug-in screw terminals

Internal data storage

- 12 GB of internal data storage for up to 360 million measurement values

- Time stamps at msec resolution

- Readout via LAN or USB interface

External data storage

- Data recorded to external storage media (USB, NAS)

- PUSH function to send measurement data to the internet

- Event-triggered recording with pre and post histories

PC and field bus interfaces

- LAN and USB interface to a PC or network

- CAN-Bus interface for reading / writing identifiers

- Field bus interfaces PROFIBUS DP, Modbus

Signal processing

- Averaging (middle, min, max, RMS values)

- Integration of time signals into volumes, masses or working values

- Computational functions (basic functions, polynomial, trigonometric ...)

Serial and SDI12 interfaces

- SDI12 interfaces for environmental sensors

- Serial ports RS232 and RS485

- Configuration of individual ASCII protocols

Remote monitoring

- Automatic notification via email or text messaging

Battery and rechargeable operation

- Independent operation possible with batteries or rechargeables

- Minimal energy consumption via a sleep function

- User-defined wake and measuring intervals

Monitoring functions

- Monitoring and data logging in a single device

- Limit value setting for any sensor signal or calculation channel

- Controlling digital outputs with user-defined triggering

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

Versions

Expert Logger – Type 100, Type 200, Type 300, Type 400

Expert Logger is available in four versions which differ only in the number of analog and digital inputs they can process. All Expert Logger devices are equipped with internal 12 GB memories that can independently store up to 360 million measurement values with date and time stamps to msec precision. Storage capacity can be extended as required via external USB or LAN storage devices (NAS). An integrated, energy-saving “sleep function“ automatically switches off the device during breaks in measurement acquisition. The Expert Logger operates with standard batteries, rechargeable batteries or solar units.

| Type | 100 | 200 | 300 | 400 |

|---|---|---|---|---|

| Analog inputs for mV, mA, thermocouples | 16 | 32 | 46 | 16 |

| Appropriate for RTD's | 8 | 16 | 23 | 8 |

| Sampling rates (measurements / sec.) | 1000 | 2000 | 3000 | 1000 |

| Analog outputs | 0 | 0 | 0 | 6 |

| Digital / Frequencies inputs | 4 | 4 | 0 | 1 |

| SDI 12 sensor bus | 1 | 1 | 0 | 0 |

| Digital / PWM outputs | 4 | 4 | 0 | 0 |

| Digital inputs / outputs | 4 | 4 | 1 | 24 |

Software

Suitable software for Expert Logger

Data acquisition and analysis

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

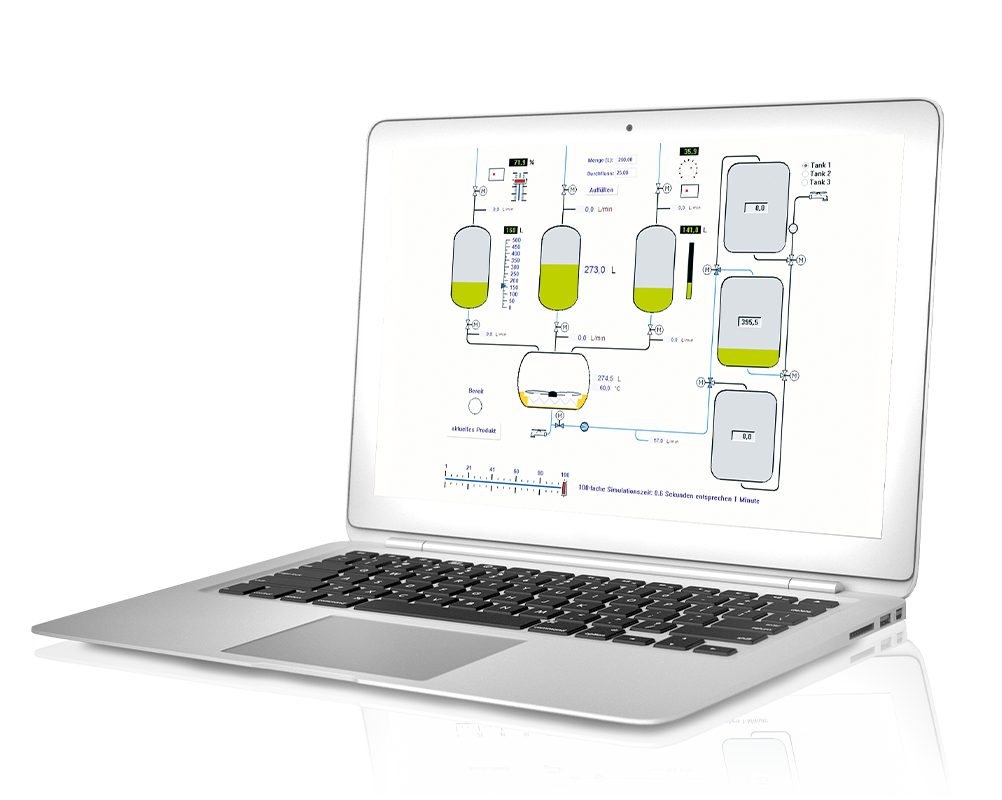

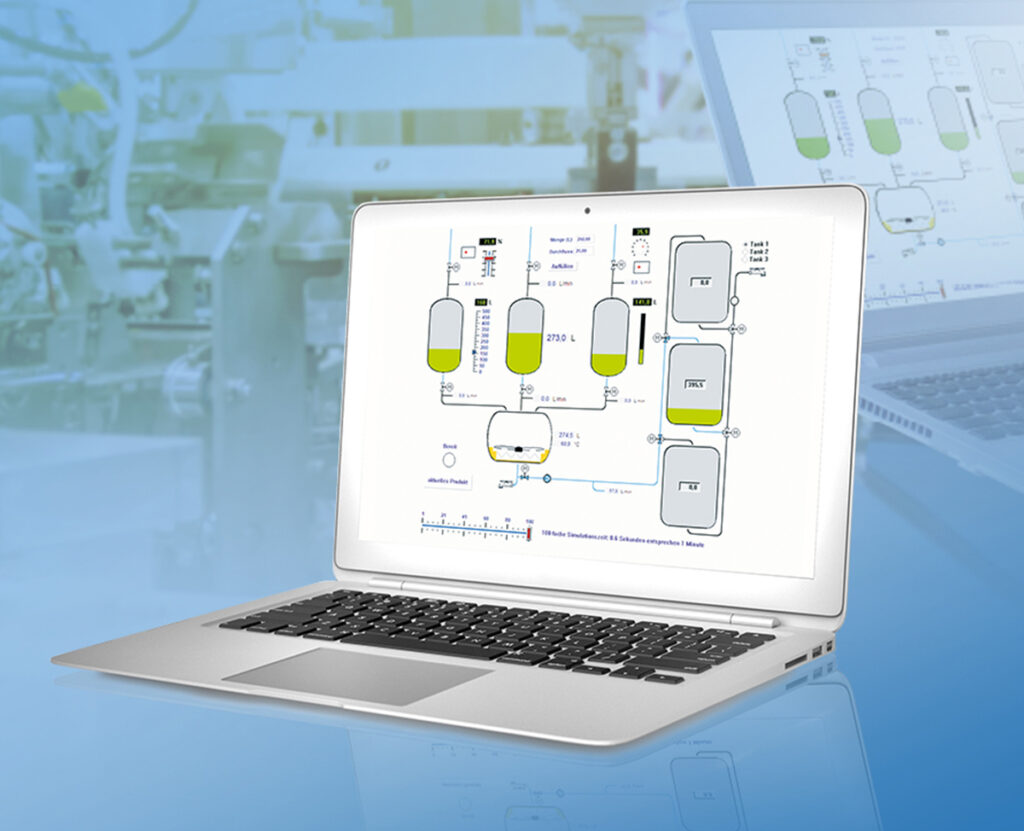

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

Automate and control

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

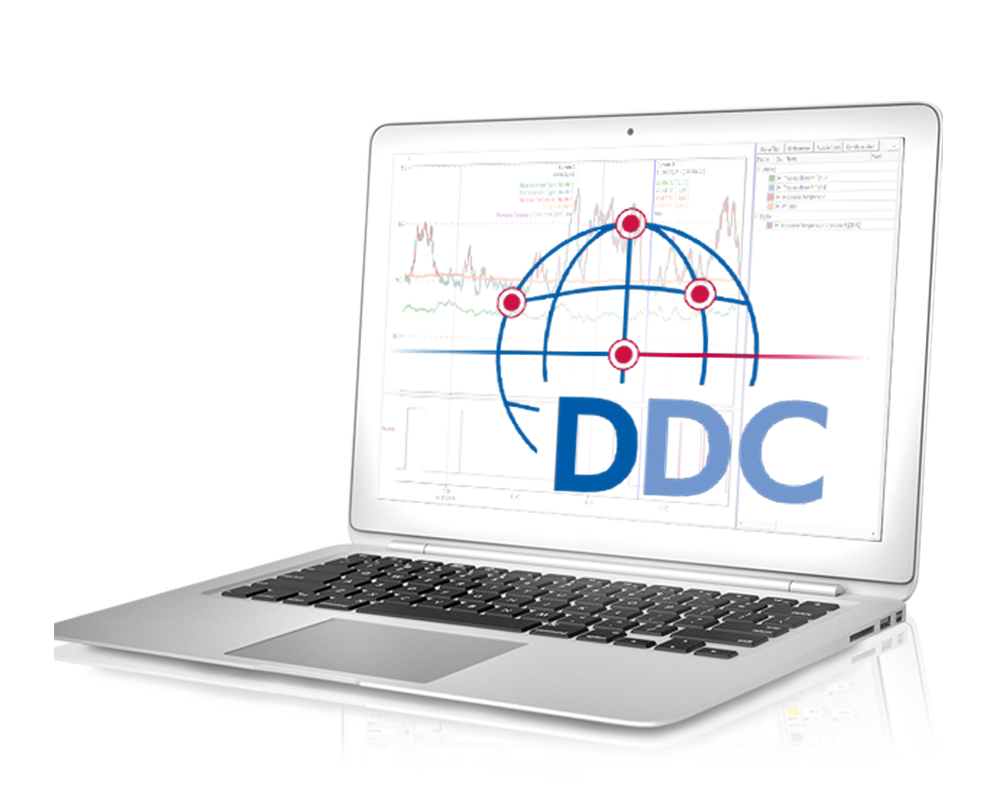

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product

Software channels as extended functions

Realise and execute monitoring and automation tasks easily

The Delphin measuring and testing devices have extended functions that are summarised under the term software channels. The online measurement data is calculated with the software channels and then used for visualisation, storage or control.

In this way, entire programme sequences can be configured very simply and intuitively with the regulation and control function. These then run autonomously without PC support. This is how you use your data logger effectively, also as a monitoring device or PLC replacement.

The software channels enable functions such as limit value monitoring, integration or online calculation and are configured very easily. This means that even users who are not experts in programming can easily implement their own monitoring tasks or balancing independently in the unit.

More informationSoftware interfaces