Modular data acquisition and automation

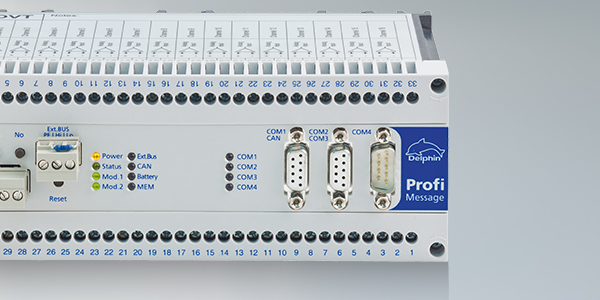

ProfiMessage devices have universal connectivity to any process. They also have flexible I/O modules and a diverse range of field bus interfaces. ProfiMessage is extremely easy to connect to PLC control systems to perform data exchange. All measurement data is recorded at high temporal resolution.ProfiMessage has integrated control, calculation and monitoring functions which make it the ideal combination device. Measurement data can be simultaneously acquired and monitored with control and regulation tasks being independently processed.

ProfiMessage devices for independent measurement and recording. Up to 14 GB data memory is able to record several million measurement values. At the click of a button the data can be transferred to a USB stick and evaluated offline. Data read outs can also take place online via an Ethernet interface. These can be performed manually or automatically according to a time plan. ProfiMessage is ideal for fast, precise and galvanically isolated measurement data, as well as for intelligent pre-processing and monitoring. Applications range from the monitoring and observation of industrial processes and machinery through to vibration measurement technology.

Product highlights

- Secure and stand alone data acquisition

- Compact and modular design

- Monitoring and automation functions

- Combined process and vibration data

- Universal analog inputs with high measurement precision

- Galvanic isolation across channels

- Simple and intuitive configuration and operation

- Ethernet interface for online operation

- USB interface for data read out

- PROFIBUS interfaces (single or redundant, according to PNO 2.212 V1.2)

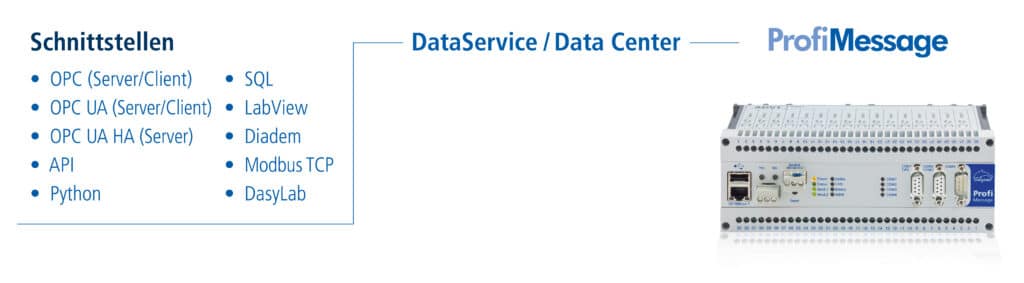

I/Os and interfaces

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

Solutions

- Modular measurement data acquisition and monitoring

- Process data acquisition and preprocessing

- Fault-data acquisition and fault diagnostics

- Acquisition, processing and recording of PLC and field bus signals

- Monitoring device for process and vibration signals

- Automation device for experiments and test stands

- Remote monitoring device for plant and machinery

Functions

Universal and galvanic isolation

A major advantage of ProfiMessage devices is that its inputs and outputs are differential, high-precision and galvanically isolated – from each other and from the power supply. Earth loops and non-isolated sensors therefore present no problems. This unique system architecture prevents earth loop distortions and enables the problem-free measurement of non-isolated signals.

Depending on the I/O module, each input can be individually configured for measuring mV, mA, RTD and thermocouples. Universal inputs for voltage, current and temperature measurement make ProfiMessage devices extremely flexible. Digital inputs are also available as status or frequency inputs along with digital and analog outputs.

Data storage functions

The integrated data memory can be partitioned and triggered to enable users to save their data either continuously or according to specified events. A drag&drop option makes it easy to assign connected channels to storage/memory groups. In the same way users can save data from virtual channels - i.e. channels that extend the functionality of data acquisition systems.

The ProfiSignal 20 software is used for both manual and automatic data memory read out. Partial and full data transfers from the data logger's memory can also be performed using a USB stick.

Redundant storage within the device means data is secure even in the event of a PC or network failure; data security is important, and not just for FDA21 CFR Part11 compliance.

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

Versions

Effective use

The ProfiLab device with 4 mm laboratory plugs is an alternative to the ProfiMessage model for mounting in cabinets on C-rails. The devices are identical apart from casings and connectors. Further information is available under technical specifications.

Depending on requirements, ProfiMessage can be used in a measurement case or as a fixed installation in a cabinet system. Delphin offers its services for individual planning and installation.

ProfiMessage -

for industry

- Industrial-grade, compact design for cabinet installations

- Screw terminals

ProfiLab -

for laboratory and mobile applications

- Laboratory-proof, robust tabletop design

- 4 mm laboratory or BNC connectors

I/O modules: Modularity and scalability

ProfiMessage master and slave devices can be equipped with two identical or differing I/O modules. A single master device can be connected with up to 20 slave devices of similar casing designs.

Data exchange between master and slaves takes place via a real time expansion bus using robust dual-wire technology. Slave devices can be decentrally located and managed from a single master device.

Seven different I/O modules are available for ProfiMessage. Each master or slave device can be equipped with two either identical or differing I/O modules.

For processing only field bus signals, master devices can be supplied without any I/O modules. ProfiMessage then functions as a PLC data logger for process fault detection and diagnostics.

| I/O-Modules | Analog inputs | Analog outputs | Frequencies / Status inputs | Status inputs | Switch outputs | Total sampling rate |

|---|---|---|---|---|---|---|

| ADGT | 8 channels, V /mV, 20 mA, RTD, thermocouples | 60 Hz | ||||

| ADIT | 10 channels, V / mV, 20 mA, RTD, thermocouples | 1 channel, 20 mA | 1 channel | 600 Hz | ||

| ADVT | 15 channels, V / mV, 20 mA, thermocouples | 600 Hz | ||||

| AAST | 4 channels, V /mV, 20 mA, RTD, thermocouples | 4 channels, 20 mA | 2 channels | 2 channels | 600 Hz | |

| IOIT | 24 channels | 1 channel | ||||

| OTPT | 1 channel | 24 channels | ||||

| DIOT | 11 channels | 1 channel | 16 channels |

Software

Suitable software for ProfiMessage

Data acquisition and analysis

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

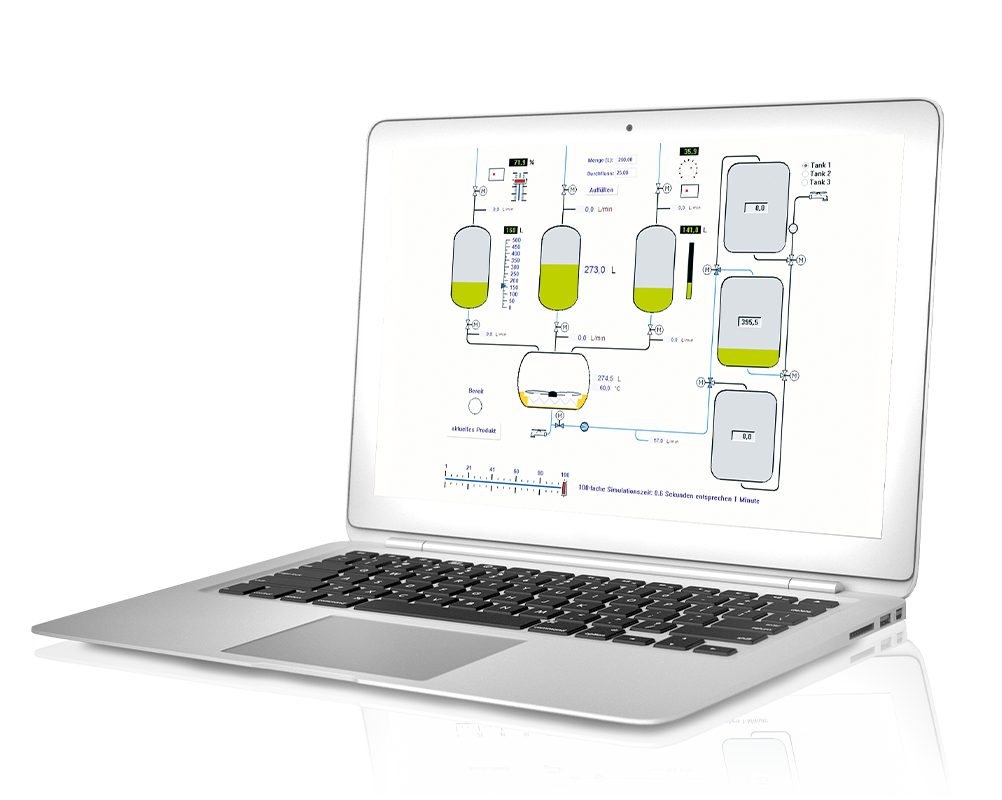

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

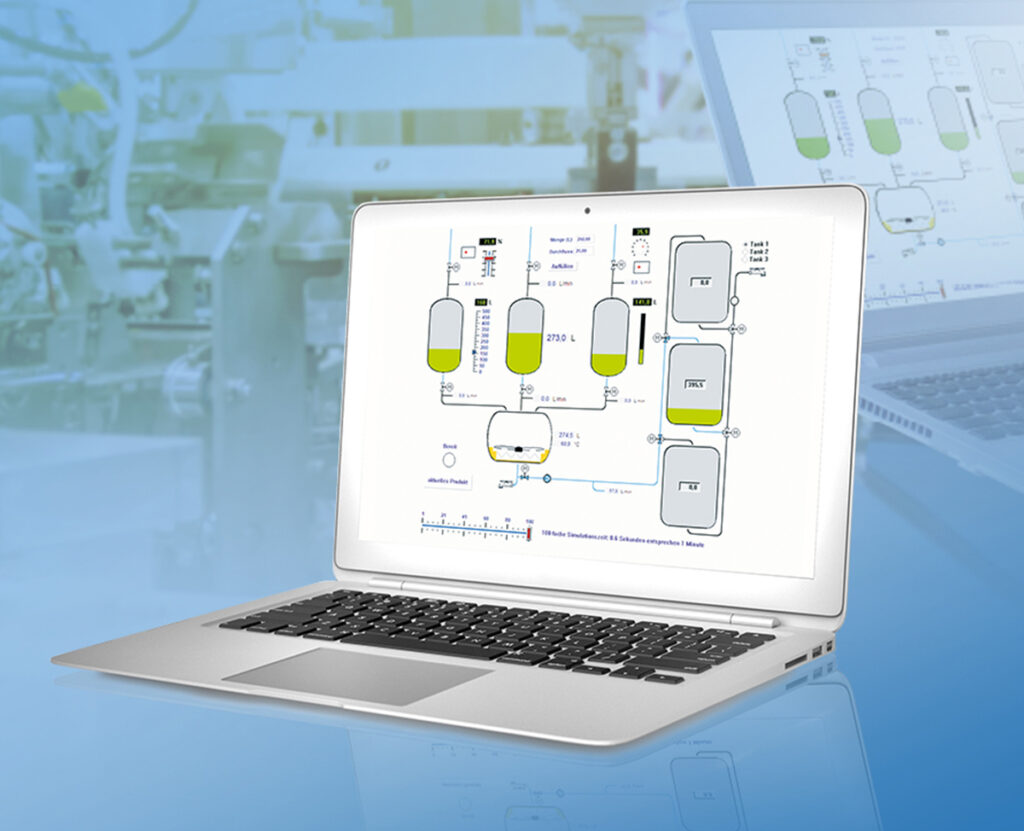

Automate and control

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product

Software channels as extended functions

Realise and execute monitoring and automation tasks easily

The Delphin measuring and testing devices have extended functions that are summarised under the term software channels. The online measurement data is calculated with the software channels and then used for visualisation, storage or control.

In this way, entire programme sequences can be configured very simply and intuitively with the regulation and control function. These then run autonomously without PC support. This is how you use your data logger effectively, also as a monitoring device or PLC replacement.

The software channels enable functions such as limit value monitoring, integration or online calculation and are configured very easily. This means that even users who are not experts in programming can easily implement their own monitoring tasks or balancing independently in the unit.

More informationSoftware interfaces