Condition monitoring in vibration measurement technology

Condition monitoring refers to the continuous monitoring and analysis of machines, plants or systems in order to evaluate their condition and performance. Various parameters such as vibrations, temperatures, pressures or lubricant conditions are recorded through the use of sensors and measuring devices. This data is then analyzed in order to detect signs of wear, malfunctions or other problems at an early stage. Condition monitoring enables preventive maintenance, as potential failures can be predicted. As a result, unplanned downtime can be avoided, the service life of systems extended and efficiency increased.

Continuous condition monitoring of machines

Vibration measurement technology is used for the condition monitoring of rotating machines. Vibration analyses provide conclusions about the condition of the system and help to detect changes at an early stage and schedule maintenance. In this way, faults can be prevented in good time, plant availability increased and maintenance costs reduced. The measurement technology used for condition monitoring differs in terms of its scope of services, its flexibility and the manufacturer's support in adapting it to customer-specific systems.

Avoid downtimes with condition monitoring

Continuous condition monitoring is essential when it comes to maximizing system availability. It detects whether system parts could fail prematurely due to wear or be damaged by vibrations. Vibration analysis enables predictive, plannable maintenance. However, a reliable condition analysis is not trivial for many systems. Rolling bearings, plain bearings and gears need to be monitored and disruptive influences filtered out in a targeted manner. The sensors, vibration measurement technology and evaluation software must be suitable and sufficiently powerful for this. Condition monitoring must also be adapted to the respective system.

Vibration measurement technology monitors system components

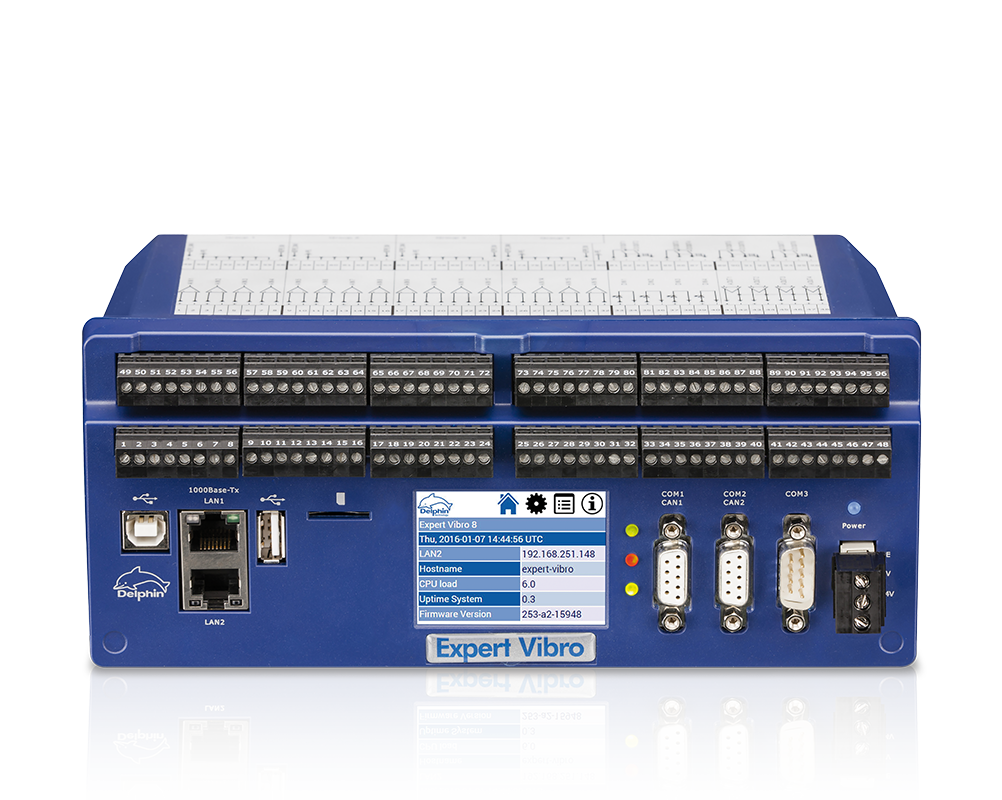

The recording and evaluation of vibrations requires powerful measurement technology. The Expert Vibro measuring device was specially developed for condition monitoring tasks on rotating machines and for vibration tasks.

- Self-sufficient local operation: Expert Vibro is very powerful and can be operated purely locally thanks to its internal memory. The sensor signals are recorded via 4, 8, 12 or 16 synchronous measurement channels with sampling rates of up to 50 kHz per channel.

- Analysis and monitoring: The measurement technology records the acceleration values and the shaft distance, compresses the data into meaningful characteristic values and evaluates them online. Set threshold values are monitored in real time and digital outputs can be switched in msec in the event of limit value violations.

- Powerful signal processing: In large systems, different components can be responsible for the unwanted vibrations. With a frequency analysis and phase determination, a more in-depth diagnosis, precise identification of individual components and a differentiated picture of conspicuous vibrations are possible.

- Software for vibration analysis: ProfiSignal is the software for measured value acquisition, analysis, visualization and automation. The additional option "Vibro" provides special visualizations for vibration measurement analyses such as Bode diagram, frequency spectrum (FFT), envelope curve spectrum or the waterfall diagram. With the ProfiSignal 20 software, measurement data can be recorded decentrally and accessed via any end device, regardless of location and platform.

High-quality measurement and testing technology for condition monitoring

- Conveyor belt monitoring: The rollers on the carriers of a baggage transport conveyor system are subject to heavy wear due to the constant loads. However, the wear and failure rate of the rollers varies greatly. To prevent the baggage transport system from coming to a standstill, each carrier is individually monitored by two acceleration sensors. The very large amount of sensor data is first pre-selected and compressed in the measurement technology and then transferred to the controller via OPC UA HA. The evaluation routines were created, tested and implemented on site by Delphin's application development team. Now the wear of the transport rollers is permanently monitored and timely maintenance is possible.

- Fan monitoring: In the production halls of a pharmaceutical company, large fans ensure that specified temperature ranges are maintained. To prevent fan failure and interruptions during operation, the drive bearings of the fans are monitored by acceleration sensors. In this way, the condition is constantly analyzed and the degree of wear is determined. Constant fan monitoring ensures that each bearing can be replaced in advance according to the degree of wear. Limit values are defined for the drive bearings, which trigger a (non-critical) pre-alarm in the event of increased wear. The pre-processed and summarized data is transmitted to the central ERP system via the ODBC interface (Open Database Connectivity). If a serious fault occurs, a main alarm is triggered and operation is stopped automatically to prevent damage to the fan.

Typical areas of application

of condition monitoring

- Monitoring systems for maximum system availability

- Condition monitoring of rolling and plain bearings

- Turbine and generator monitoring

- Pump test stands

- Gearbox test stands

Maximum flexibility for condition monitoring

The Expert Vibro measuring device was developed for the most flexible use possible. Depending on requirements or for in-depth analyses, it can record data from different sensors and combine vibration and process data. In addition to acceleration sensors, temperature, eddy current, structure-borne sound, force, pressure and flow sensors or measuring microphones in accordance with the IEPE standard (Integrated Electronics Piezo Electric) can also be integrated, for example. Thanks to data acquisition with 24-bit resolution and very high sampling rates, vibration and process measurement values can be recorded and evaluated synchronously in one system.

Condition monitoring and IIoT

The Industrial Internet of Things (IIoT) plays a decisive role in the further development of condition monitoring systems. IIoT enables machines and systems to be networked, allowing comprehensive data to be collected and analyzed in real time. By integrating sensors and other devices into the IIoT, condition monitoring systems can continuously collect data on the condition of machines. This data is then transmitted via the internet to a central platform or cloud solution, where it is analyzed and evaluated.

The advantages of IIoT for condition monitoring are manifold. On the one hand, it enables comprehensive monitoring of large systems or machine parks, as data from different locations can be collected and analyzed centrally. This allows potential problems to be identified at an early stage and maintenance measures to be planned in a targeted manner.

In addition, the IIoT enables the integration of advanced analysis techniques such as machine learning or artificial intelligence. These technologies can process large amounts of data and identify patterns or anomalies that would be difficult for human analysts to recognize. This further improves the efficiency and accuracy of condition monitoring.

Another advantage of IIoT is the possibility of remote monitoring. By networking machines, status data can be monitored in real time, regardless of location or time zone. This enables a faster response to problems and more effective planning of maintenance measures.

Overall, the IIoT is making a significant contribution to the further development of condition monitoring systems by enabling comprehensive data collection, advanced analysis techniques and remote monitoring. This enables companies to operate their systems more efficiently, reduce downtime and extend the service life of their machines.

Adapt vibration measurement technology to the system

Depending on the application, very different adaptations may be required to monitor the condition of a machine or system. In practice, this often involves plant-specific sensors, connection to an existing database system and connection to the plant control system.

The measurement technology from Delphin provides the interfaces for this, such as OPC UA, Modbus RTU, Modbus TCP, PROFIBUS or CAN. OPC UA (HA) and ODBC are supported on the software side. If required, Delphin's application development team provides support to ensure that the measurement technology can be adapted to the respective system as quickly and easily as possible.

Powerful and compact measurement technology

Condition monitoring with vibration measurement technology requires particularly powerful measuring equipment. In addition to data acquisition, this involves fast processing of very large amounts of data, online pre-processing, characteristic value calculations, special analysis methods such as phase angle determination, evaluation of high-resolution frequency spectra (FFT) and real-time alarm processing when limit and threshold values are exceeded. Thanks to very compact dimensions, as with the Expert Vibro measuring device (217 x 88 x 128 mm), no additional control cabinet is usually required.

Hardware and software for your measurement and testing solution

Flexible, scalable and expandable solution for seamless data acquisition and monitoring

The Loggito device is a compact data logger system designed for the acquisition and recording of measurement data. It has a variety of analog and digital inputs to connect different sensors and signals. The device records the data with high accuracy and stores it on an internal memory or external storage media such as SD cards.

To the product

Data acquisition and analysis

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

Precisely record, autonomously store, automatically transmit and evaluate measured values.

The FPGA-based Expert Logger device is particularly powerful and enables the processing of up to 46 analogue input channels, both at low and high sampling rates. Measured values can be precisely recorded, autonomously stored and automatically transferred to the internet or PC via USB, LAN or WLAN and evaluated.

To the product

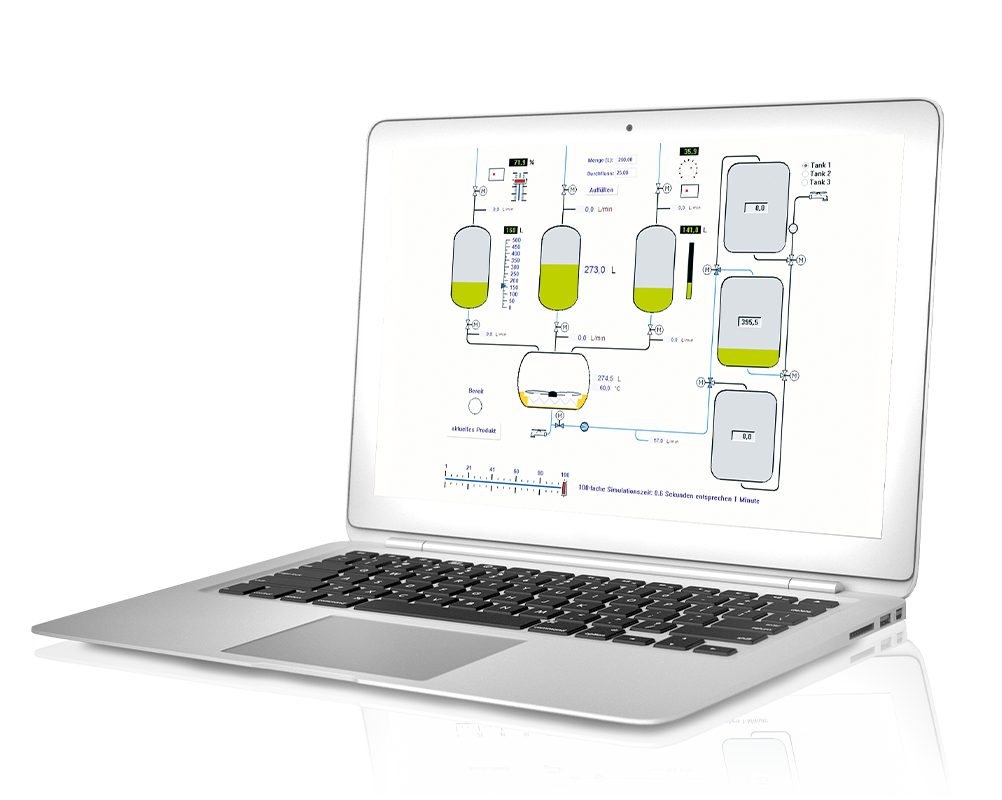

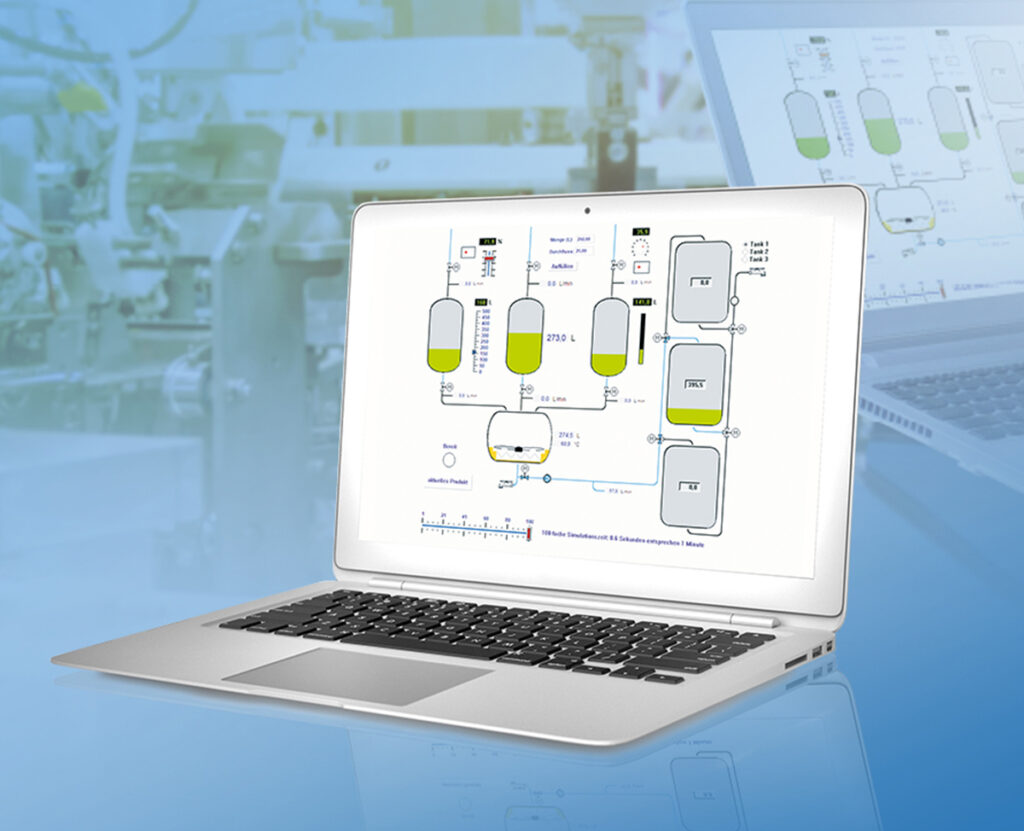

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

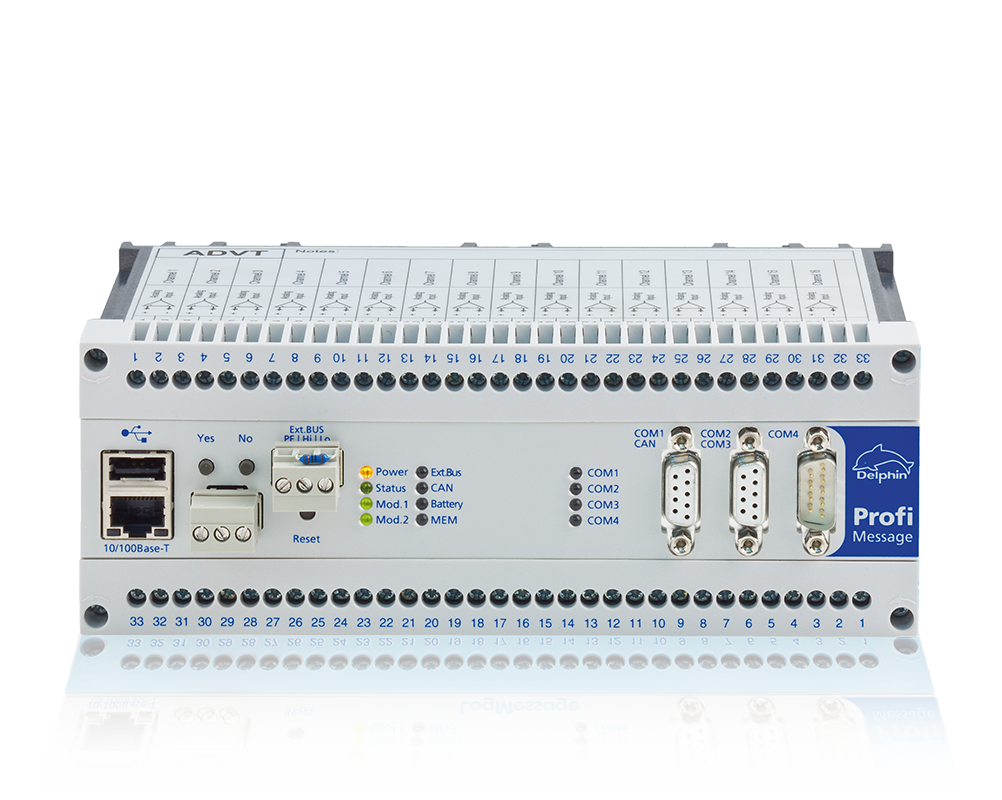

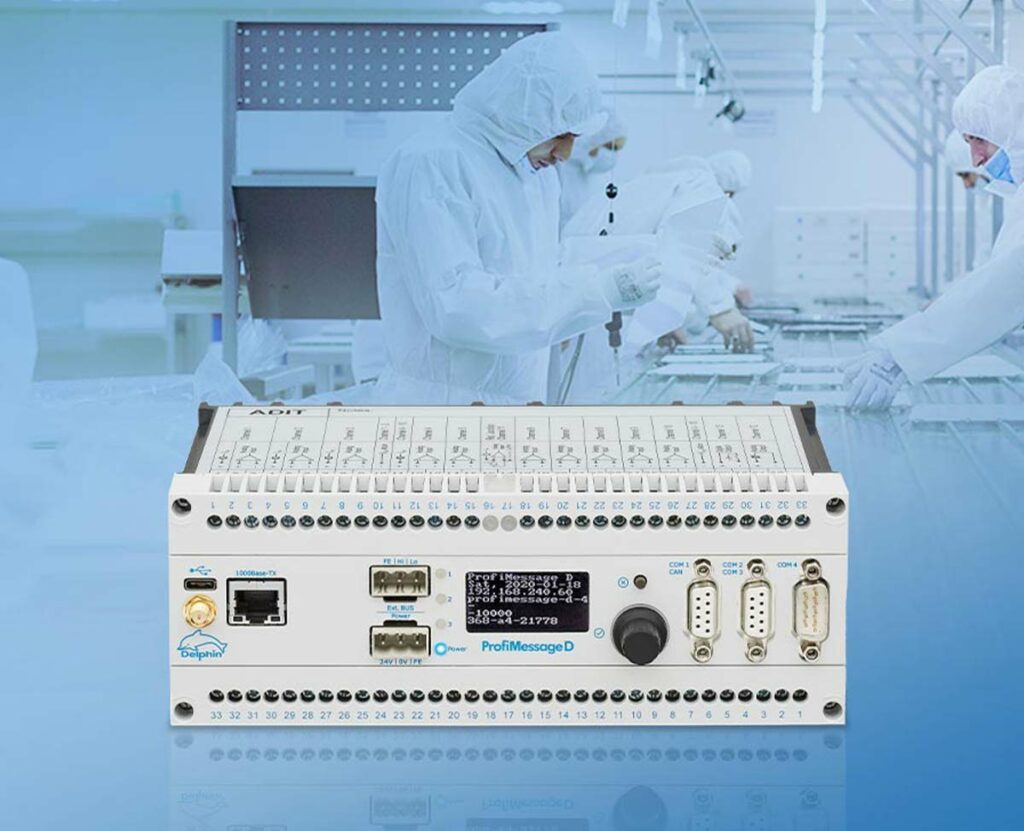

Modular measuring, monitoring and automation in one device.

The ProfiMessage D device is a state-of-the-art data logger system that has been specially developed for industrial data acquisition and analysis. It offers a wide range of functions such as the recording and storage of measurement data, monitoring of process parameters and alarms in the event of deviations.

To the product

Automate and control

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

State-of-the-art processor technology and extreme precision for vibration measurement.

The Expert Vibro device is a powerful vibration analysis device that has been specially developed for monitoring and analyzing machine and system conditions. It enables vibration data to be recorded and evaluated in order to detect potential problems or signs of wear at an early stage.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

Intelligent data recorder for synchronous recording of transient and periodic events.

The Expert Transient device enables the recording and evaluation of transient signals over a certain period of time and provides important information for the optimization of processes and systems. The device is characterized by its high accuracy, fast sampling rate and simple operation.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

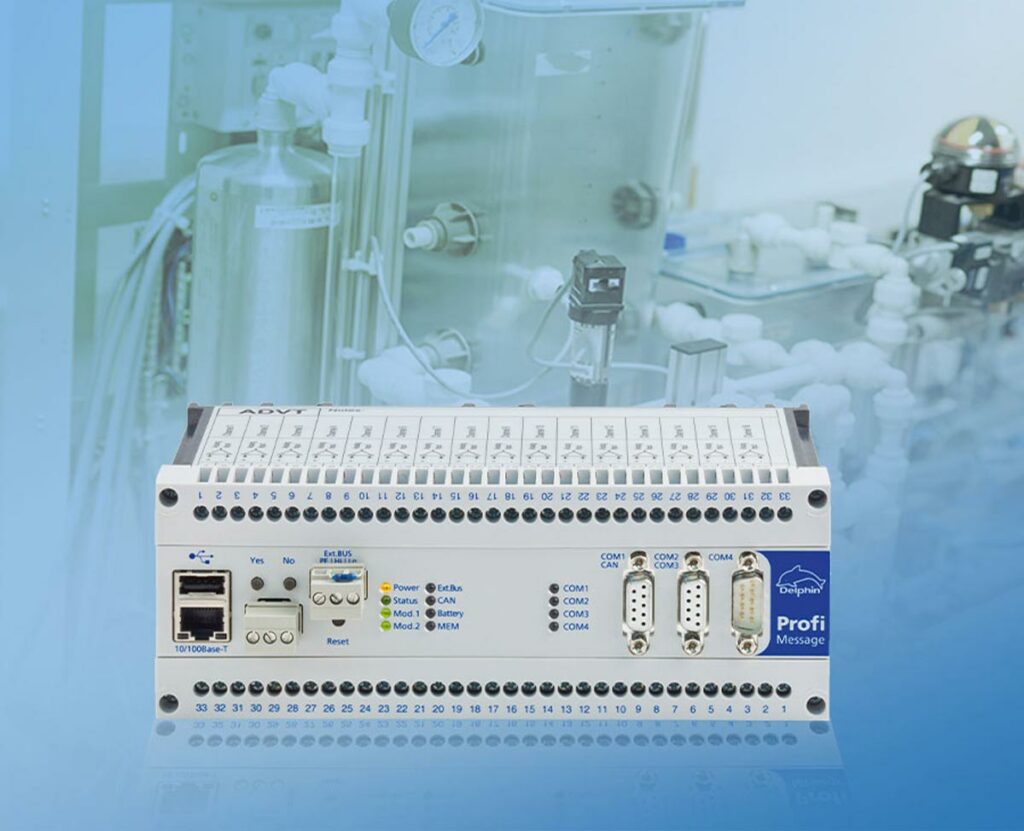

Modular system for use as a measuring, control and monitoring device.

The ProfiMessage devices are a modular, expandable and easy-to-use system for measurement data acquisition, monitoring and automation of machines, systems or test benches. ProfiMessage can be used wherever measured values need to be recorded quickly, precisely and electrically isolated, as well as intelligently pre-processed or monitored.

To the product

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product

PC-supported data acquisition and test stand

The Expert Key device is a measuring and control device that can be used in various applications. It enables the acquisition and evaluation of measurement data as well as the control of processes. The device has various interfaces and can be connected to a wide range of sensors and actuators. It is often used in automation technology, mechanical engineering and research.

To the product

Compact and flexible measurement data laboratory with precision measurement technology.

The LoggitoLab device is ideal for use in laboratory environments, research projects, quality control and other applications where precise data acquisition and analysis is required. It offers a reliable and user-friendly solution for monitoring and recording measurement data.

To the product

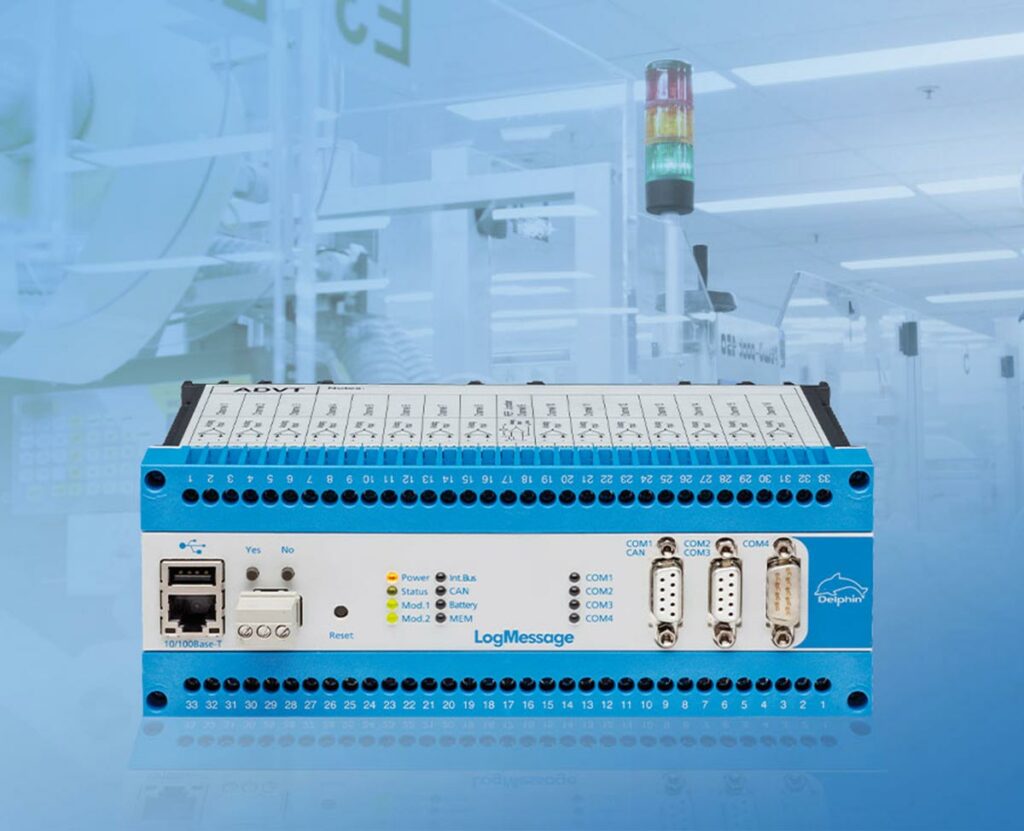

Test stand for measurements with potential using an internal data memory.

The LogMessage device is a powerful data logger system designed for the reliable acquisition and recording of measurement data. It offers a variety of analog and digital inputs to connect different sensors and signals. The device records the data with high accuracy and saves it to an internal memory or external storage media.

To the product