What is a data logger?

Data loggers are electronic devices that have an integrated, processor-controlled memory unit, one or more interfaces and at least one channel for connecting a data source. These features distinguish them from simple measuring devices. Data loggers record data over a predefined period of time and store it for later use. Data loggers are used to record physical measurement data (temperature, acceleration, pressures, etc.) or digital information.

Historical development of data loggers

Even if modern, high-performance data loggers suggest otherwise: The development history of electronic devices goes back to the early 20th century! This is because analogue recording devices such as data recorders were already being used around 1900 to record various measured variables reliably and with minimal time expenditure. Especially in industry and research.

The development of data loggers only picked up speed after the Second World War. The invention of transistors and their further development into the early 1960s "electrified" the previously purely mechanical data recording process. Over the course of the 1960s, it became possible to mount more and more transistors in ever smaller spaces. Transistors can be seen as the origin of digital technology thanks to their ability to react quickly. Consequently, it did not take long - until 1965 to be precise - before the first data loggers were developed that could digitize analogue signals and store them on a medium, the magnetic tape commonly used at the time.

Unlike data loggers, magnetic tape had no future. The compact cassette replaced the bulky, stationary and space-consuming magnetic tapes in the late 1960s. Compact cassettes as a storage medium for data loggers are documented from 1966 onwards. The compact cassette remained the standard storage medium for data loggers for more than a decade - until the advent of "Electrically Erasable Programmable Read-Only Memory" technology, or EEPROM for short. The invention of EEPROM represents a technological leap for data loggers. Previously dependent on a permanent power supply and therefore not very mobile, data loggers with EEPROM as a storage medium could also be used without a permanent supply voltage. Finally, in the 1980s, another innovation emerged that is still used as a storage medium in data loggers today: Flash EEPROM. Flash EEPROMs, also commonly known as flash memory, store information persistently, i.e. non-volatile, in a small space and do not require a permanent supply voltage.

The introduction of the first home computers in the 1980s, such as the Macintosh 128k or the Commodore 64 (C64), also brought about a lasting change in the field of measurement technology. Thanks to the more readily available processors and programming options, it was no longer just possible to build measuring devices or data loggers that simply stored data. From this point onwards, it was possible to record more complex data and pre-process it in the device at the same time.

Delphin Technology was one of the first companies to successfully build the first data loggers using the MCS6502 processor (based on the C64).

The transformation of processors as the heart of data loggers or data recorders, measuring devices and programmable logic controllers (PLCs) marked the beginning of a new era in measurement, control and regulation technology.

Today, no data logger or PLC can do without processors. The difference between data loggers and a PLC is sometimes blurred. Today, control and regulation tasks can also be performed by powerful data loggers. For example, powerful data loggers are used as small controllers. One example of this is the Expert Logger from Delphin, which is used for high-precision measurements where control and regulation tasks have to be performed simultaneously.

If large systems with many sensors and actuators are to be monitored and supervised, devices such as the ProfiMessage D are used. The ProfiMessage D is a modular, expandable system similar to a PLC, but with extremely powerful measuring functions.

As automation progressed in the 1990s and the availability of large amounts of memory and processor capacity improved, data loggers can no longer be seen as the sole solution for measurement and control tasks. The focus is increasingly shifting to the interaction of measurement data acquisition in conjunction with powerful DAQ measurement technology software.

Today, networked data loggers can easily set up a system or global data network that enables condition monitoring with the appropriate software. One software that makes this possible is the Delphin Data Center in combination with the ProfiSignal 20 measurement technology software.

What are standard signals?

In order for physical process variables, such as temperatures, humidity or pressures, to be processed by evaluation devices, they must be converted into standardized electrical signals. These signals can be transmitted either as current or voltage signals.

In the vast majority of applications, current signals are preferred to voltage signals. The advantage of current signals is their insensitivity to electromagnetic interference. Voltage losses due to line resistances are also not to be expected with current signals.

How does a data logger work?

The functionality of a data logger always depends on its intended use and the associated type of data recording. A basic distinction is made between the recording of data:

- Digital sources

- Analog sources

Data loggers that record digital information are connected directly to the computing unit that generates the data via an interface. Data recording and storage on the storage medium is controlled by software.

Data loggers that are intended to collect and store analog information, such as temperatures, humidity or machine parameters, are connected to additional sensors via the inputs (0-20 mA, 4-20 mA, 0-10 V, ...). These sensors record the physical, analog, binary information and forward it to the data logger via the interface. Here the data is first digitized, then processed and stored.

IoT data logger for use in Industry 4.0

The fourth industrial revolution, Industry 4.0 for short, is in full swing. The networking and communication of machines, systems and devices via the internet is the focus of Industry 4.0, and the requirements for modern data loggers are correspondingly diverse. As part of the IoT (Internet of Things), the data loggers should be flexibly adaptable to the respective areas of application, and the devices must also be networkable - and have communication options with other IoT devices and the end user. With the Expert Logger in combination with the ProfiSignal 20 software, Delphin offers the answer to the requirements of networked, digital industrial environments.

With the Delphin Expert Logger or Loggito, data logger systems are available that

- access to the measured values via mobile devices.

- 16 to 46 analog inputs for autonomous data acquisition from any sensors.

- communicate continuously with the company's cloud.

- and also have internal data storage to prevent data loss if the connection to the cloud is interrupted.

- serve as a small controller with digital and analog outputs or replace a PLC.

Read this article to find out what the modern IoT data loggers from Delphin Technology can do in detail.

The data logger as an EDGE device

In the Internet of Things, edge devices handle the transportation of data packets between different network structures. Edge devices use processors to process sensor data directly at the application at the edge of the network, making the processing and control of the enormous amounts of data generated more efficient. In Industry 4.0, edge devices take on tasks in the areas of connection and gateway. Specifically, this involves converting the data provided by fieldbuses into IP-based data traffic. Would you like to find out more about the wide range of possibilities that Delphin Technology offers you through innovative technology and powerful software in the field of edge devices? Click here and immerse yourself in the world of SCACH!

How does data get into the data logger?

Data is recorded via the interface(s) and can be recorded in two ways:

- External - the data logger is connected to external sensors via the interface.

- Internal - the data logger forms a compact unit with the sensor.

Which interfaces are used for data loggers?

The type of interface of a data logger is determined by the intended use, whereby data loggers can also provide several interfaces. In industry and manufacturing, serial interfaces such as RS-232 or RS-485 are common, as are USB connections, mobile data networks (UMTS, LTE, 4G, in future also 5G), Wi-Fi or Industrial Ethernet. The variety of interfaces already gives an idea of the wide range of possible applications for data loggers.

Which data exchange standards can data loggers use to communicate?

Modern data loggers are equipped with different industrial standards for data exchange, depending on their intended use. There are simple data loggers that are only designed to record a very specific value and have little or no communication interfaces. Modern professional and highly accurate data loggers have a powerful processor similar to a PLC and can actively participate in communication in the measurement network. Common options include the secure communication protocol OPC UA (Open Platform Communications Unified Architecture), ProfiNet, CAN bus or Modbus.

How does the power supply for data loggers work?

The power supply of a data logger depends on its intended use and the power consumption during operation. Stand-alone data loggers for mobile use use batteries for the power supply, stationary data loggers are connected to the mains using a cable and power supply unit. The required power consumption of data loggers can vary greatly for various reasons. If data loggers with galvanic isolation are used, the power consumption is significantly higher for this reason alone. The connected sensors and the required sampling rate can also lead to higher power consumption.

Inputs and outputs on data loggers

Inputs and outputs on data loggers, also known as I/Os, are used to record measurement data (inputs) or to control systems or actuators (outputs).

Analog inputs

Depending on the required application, data loggers have one or more inputs for connecting sensors. The Loggito from Delphin Technology, for example, offers up to eight multifunctional analog inputs to which different sensors and measured variables can be connected in parallel. For more extensive measurement tasks, the Delphin Expert Logger up to 46 analog inputs. The current measuring ranges of the devices are 0 - 20 mA or 4 - 20 mA.

Outputs

If data loggers are used for the continuous monitoring of systems or machines, the devices should not only record and store data - they should also be able to actively control actuators. Data loggers with corresponding outputs can significantly increase the degree of automation as part of the overall system network.

The galvanic isolation of the inputs and outputs of a data logger

With galvanic isolation, two conductive objects are decoupled from each other or the electrical line between two circuits is separated. Galvanic isolation is also necessary for data loggers in some cases:

- Measuring sections with an earth reference: Any earth potential differences that occur here can cause distortions. So-called earth current loops can lead to incorrect evaluations of the signal.

- Interlinking of several measuring circuits: Reference potentials can be raised undesirably here.

- Applications with long cable runs or in EMC-loaded environments: Inductive or capacitive interference can occur in the measuring circuit

The electrical isolation of the inputs and outputs ensures separation of the electrical potentials and potential-free circuits. Galvanic isolation is necessary for reliable measurement technology. More about the You can find out more about galvanic isolation in this article.

What are the actual differences between data loggers?

Data loggers are available in various designs and are configured differently depending on the application. The particularly small, compact and inexpensive disposable data loggers, for example, are optimized for one-time use in transportation, while the larger, more expensive multi-channel data loggers can measure and store different values. Other data loggers have integrated sensors or are waterproof (encapsulated).

Another distinguishing feature is the memory. Data loggers that are used autonomously (for transport monitoring or similar) are usually equipped with a module for storing the collected data. Stationary data loggers that are directly connected to a computer, on the other hand, do not require this memory - the data is generated by the data logger and immediately forwarded to the connected computing unit.

Data logger as MSR devices, PLC or small controller

Some data loggers can not only collect and store data, but can also be used as an MCR device / controller. I&C (measurement and control technology) devices are able to record data and use it to control systems or machines thanks to powerful integrated processors and a wide range of connection options for sensors. A simple application example is heating technology: if a sensor detects that a certain temperature has been exceeded or fallen below, the heating system is automatically regulated up or down accordingly. In industry, data loggers with PLC functions are used to increase system availability, reduce energy consumption or increase running times.

What data loggers are available and what are they used for?

Multifunctional data logger

Multifunctional data loggers have several interfaces so that distributed, different measuring points can be monitored. Multifunctional data loggers are able to record data via different sensor types and are ideal for the cost-effective construction of decentralized measurement networks. All data loggers built by Delphin Technology can be classified as highly accurate multifunctional data loggers. They offer all the functions of the data loggers listed below. In addition, they are characterized as PLC replacements.

Data logger temperature

Temperature data loggers are primarily used in industry for monitoring temperature-sensitive environments, for example in the drive areas of machine tools or systems.

Temperature and humidity data logger

Data loggers for temperature and humidity record both temperature and humidity conditions, thereby significantly expanding the possible areas of application for these data loggers.

GPS data logger

GPS data loggers use a separate module to permanently transmit their own location and record any events that occur. In addition to the benefits of location determination, GPS can also be used to synchronize the time of data acquisition to the millisecond. Many data loggers for general measurement applications can often be equipped with an additional GPS module.

Data logger LTE, 4G, 5G, mobile communications

These data loggers use the fast data standards LTE, 4G or 5G to transmit the collected data. LTE 4G 5G data loggers are suitable for location-independent use in logistics, industry or the construction sector. The self-sufficient data loggers enable fast data transfer, making it possible to assess measuring points from a desk via remote maintenance.

Data logger for vibrations

Data loggers for vibrations are used for the optimization and monitoring of machines, systems or vehicles, among other things. By recording oscillation and vibration, data bases are created for the optimization of motors, bearings or drive spindles. Data loggers for vibrations are often used in condition monitoring.

Data logger vehicles / transport logger

Data logger vehicles / transport loggers enable the detection and logging of vibration or shock events during the transportation of goods, merchandise or the tracking of vehicles.

Photovoltaic data logger

Photovoltaic data loggers are used to monitor solar power systems. These data loggers can provide information on solar power production, the status of the system or the fill level of a storage battery.

Data logger vaccine

Vaccine data loggers are indispensable in the monitoring of refrigerators or freezers for the storage of vaccines.

Data logger climate mapping

Climate mapping data loggers are highly specialized devices that record the temperature distribution and humidity within a predefined range.

High temperature logger

High-temperature loggers can be used in areas with significantly higher temperatures. Depending on the equipment and application, high-temperature loggers can be used at temperatures of over 400° C.

Shock data logger

Shock data loggers record vibrations. Shock data loggers are used on transportation routes, for example, to detect strong vibrations to which products are exposed during transport.

Pressure data logger

Pressure data loggers are used to monitor pressures, for example water pressure or compressed air. Pressure data loggers are used for leak tests, fault analysis in pipelines or for monitoring the function of air pressure systems, among other things.

Pharma data logger

Pharma data loggers are optimized to meet the high requirements of the pharmaceutical industry. Pharma data loggers are used for process monitoring or high-precision monitoring of manufacturing processes.

Data logger acceleration

Acceleration data loggers are used to assess mechanical-dynamic loads on an object. For this purpose, acceleration data loggers are equipped with acceleration sensors that record the current acceleration acting on the sensors in the event of shocks or vibrations.

CO2 data logger

CO2 data loggers are used as part of an air quality check in work or recreation rooms, offices or schools. CO2 data loggers measure and store the proportion of carbon dioxide in the ambient air.

Disposable data logger

Disposable data loggers are cost-effective data loggers that are designed for single use. Disposable data loggers are used, among other things, to monitor goods in transit or during storage.

Multi-channel data logger

A multi-channel data logger can be used to control different sensors and thus measure and record different information with one device.

Accuracy of the measurement for data loggers

The accuracy of a data logger is defined by the deviation of a value generated by measurements from the actual value of the measured variable. The smaller this deviation is, the more accurately a data logger measures. The devices in the Loggito series from Delphin Technology, for example, offer the following accuracies:

- Resistance measurement: 0.01% of the measuring range end value for 4-wire connection, 0.1% of the measuring range end value for 3-wire connection

- RTDs: 0.1 K for 4-wire connection, 1K for 3-wire connection

What does speed or sampling rate mean for a data logger?

The speed or sampling rate of a data logger indicates the time intervals at which a measurement is carried out. The higher the sampling rate, the finer the resolution of an event. However, too high a speed during measurement can also be a disadvantage, as it automatically results in an increased volume of data, which is a disadvantage if the data logger cannot handle the processing in the long term or the DAQ measurement data software connected to the measurement network is not designed for the volume of data transferred. A high sampling rate also increases the power consumption of the data logger, which can limit the operating times of mobile devices with rechargeable batteries in particular.

Data loggers from Delphin use fast processors to process the recorded data directly in the device to avoid excessive data volumes. Adaptive storage can be used for this purpose. With adaptive storage, only data points that deviate from the previous ones are written in full to the memory. This procedure compresses the measurement data without loss and stores it in a small size.

Which sensors are available for data loggers?

A sensor is a technical component that can be used to record physical or chemical properties or the nature of the environment as a measured variable. A sensor records the measured variables that occur through biological, chemical or physical processes and converts them into electrical signals. The areas of application for data loggers are extremely diverse, and the range of sensors is correspondingly extensive. Widely used sensors for data loggers are

- Temperature sensors

- Material moisture electrodes

- Climate sensors for temperature and humidity

- CO2 sensors

- Puncture sensors

- Shock sensors

- Air pressure sensors

- Acceleration sensors

- Vibration sensors

The right software for DAQ measurement data acquisition and storage

With modern measurement data software such as ProfiSignal 20 from Delphin Technology, measured values recorded by data loggers can be analyzed and visualized intuitively and independently of the platform, making it easy to monitor and control processes.

The ongoing digitalization of industry calls for software solutions that also centralize the management of data collected from machines, systems or measuring stations. Integrated solutions that impress with a variety of interfaces, cross-system user management and maximum scalability and expandability are particularly in demand for continuous condition monitoring. With the DAQ Delphin Data Center (DDC), as one of the most powerful DAQ measurement data software, distributed sources of measurement data can be networked, monitored and analyzed.

Thanks to the open structure of the data pool, the Delphin Data Center enables the standardization, archiving and monitoring of measurement and process data - either locally or with worldwide access. The Delphin Data Center also offers the advantage that almost all data from a plant network can be recorded and processed in a structured manner. Regardless of whether the data originates from Delphin devices, a PLC or other data loggers. Common standards such as OPC UA, Modbus, ProfisNet, ProfiBus, CAN, ... are supported.

Do data loggers need to be calibrated?

Data loggers are calibrated to ensure that the measured values recorded by the data loggers are as precise as possible.

A specification for repeating the calibration depends on the manufacturer and device as well as the operational specifications. It is advisable to have the data logger recalibrated at least once a year, especially for demanding or critical applications. Depending on the operational use, regular calibration of data loggers is necessary for reasons of liability.

For calibration, the data loggers are compared with a reference measuring device and calibrated at the factory or in a certified laboratory.

The values recorded by the reference measuring device at the measuring point, the values recorded by the data logger at the same measuring point and the difference between the two values are recorded in a calibration certificate.

Software for your measurement and testing solution

Data acquisition and analysis

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

Automate and control

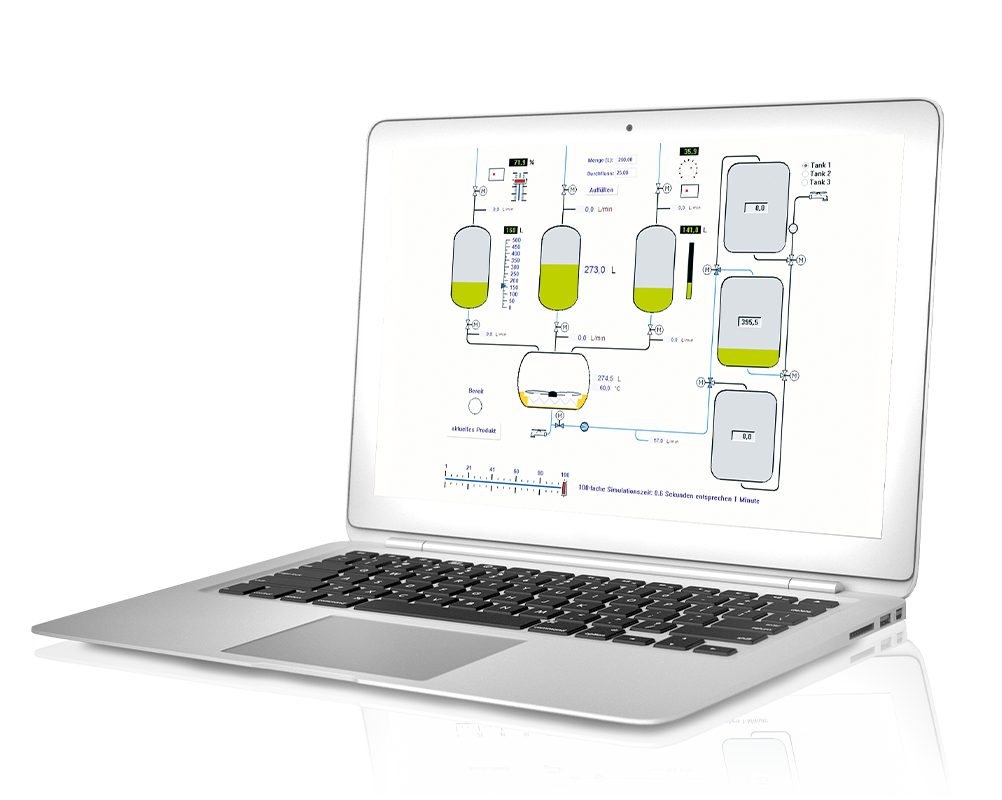

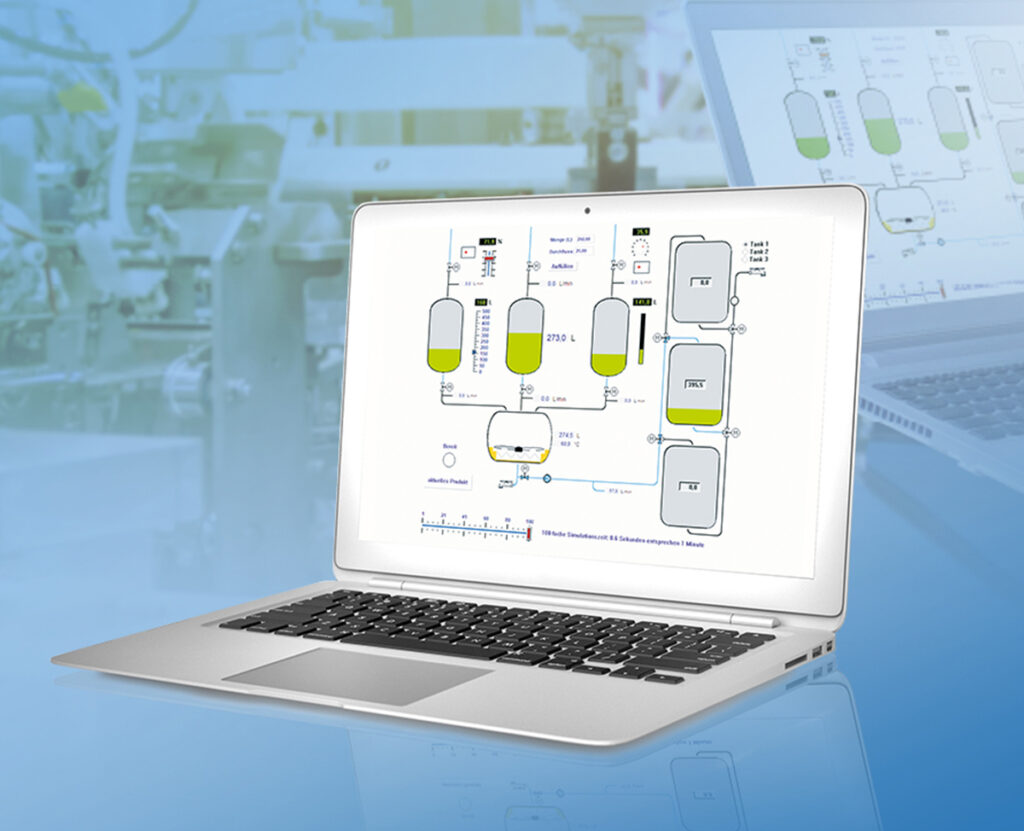

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product