Remote monitoring and remote maintenance in an industrial environment

Productivity in manufacturing is largely determined by the efficiency of the production machines and systems used. Only if the capacity of the means of production is optimally utilized will the economic efficiency be right. To achieve this, a wide range of machine parameters must be recorded and then analyzed. In the course of the digitalization of production and the ever-increasing networking of machines and systems among and with each other, new solutions are being developed to optimize the productivity of the "smart factory".

Alongside condition monitoring and process monitoring, remote monitoring and remote maintenance are among the digitally driven options for making manufacturing processes leaner, more efficient and more reliable. Delphin Technology supports the digital revolution in industry with intelligent, high-performance concepts that enable remote monitoring and remote maintenance in production without replacing existing control and automation hardware.

What exactly does remote monitoring mean in production?

Remote monitoring describes the ability to monitor, control and adjust production processes on a machine in real time, regardless of location. Production processes include both work steps of a production order as well as machine statuses or material flows within a production line. Remote monitoring is based on hardware and software solutions specially adapted to the needs of the industry. Through the optimized interaction of hardware components installed directly on the machines, IoT devices or edge solutions and software-based platforms or the cloud, data can be recorded, collected and analysed directly from production. If interventions in the production process are necessary, these can be carried out in many cases without the need for an operator to be present directly at the machine or system.

What is remote maintenance?

To ensure machine or system availability, it is necessary to rectify existing faults promptly - or to ensure that faults do not occur in the first place. Remote maintenance is a remote service in which service technicians can access the machines and systems to be maintained via the internet. The machine or system uses sensors to collect extensive data, which is used for quick fault diagnosis during remote maintenance. If there are incorrect settings, these can be resolved via remote access or by giving instructions to the machine operator. Many machine manufacturers now offer remote maintenance as a service. This also allows manufacturer-specific settings in the control systems to be adjusted and optimized without expensive, time-consuming and disruptive on-site technician visits. Companies such as Delphin Technology support system manufacturers in implementing remote maintenance solutions for their products.

How does remote monitoring work in practice?

Regardless of the machines or systems used and the ongoing production processes, remote monitoring works in practice through the interaction of:

- Sensors

- data loggers

- Data storage (server or cloud)

- Merging the data

- Preparation and visual presentation of the data obtained using software

Every remote monitoring system begins with the recording of physical measured values in the work area, on the motors or axes of a production machine. Various sensors are installed to record parameters such as temperatures, pressures, oscillations, vibrations or speeds. It is also common to obtain measurement data from the PLC or CNC systems used - no additional sensor is required for this. The collected measured values are then forwarded to a data logger. Electronic data loggers such as the Loggito Logger from Delphin Technology collect and store the measured values transmitted by the sensors.

The data logger converts the physical measured values into data records and forwards them to a server or the cloud. The process of converting, forwarding and processing measured values from the analog world for digital use is known as DAQ - Data Acquisition. In the industrial environment, specialized DAQ software solutions such as the Delphin Data Center from Delphin Technology enables the reliable, highly precise and loss-free merging and processing of a wide variety of data sets. The data collected on the server or in the cloud is then automatically prepared for analysis or visualization tasks. Regardless of location and with customizable display options, production processes, operating states or even sources of error can be visualized in great detail.

Can current and older machines or systems also be used for remote monitoring?

Many manufacturing companies use machines or systems that are not designed by the manufacturer to be connected to the IoT. The average life cycle of a machine tool, for example, is 25 to 30 years. Particularly in the case of capital goods such as lathes or milling machines, injection molding machines or wind turbines, a lot of technology from the 1990s or early 2000s is still in use in Germany. However, some industrial plants with PLC control systems also do not have the option of remote maintenance. These machines and systems lack the manufacturer's interfaces for data transfer, and the control systems used are rarely designed for remote maintenance or remote monitoring. Nevertheless, it is possible to monitor older machine tools and systems - without having to replace the existing control and automation hardware, without extensive downtimes in production or retrofitting by the manufacturer.

With the products from Delphin Technology, even older machines and systems can be used for modern, digital remote monitoring or remote maintenance. The perfectly coordinated Delphin systems, developed to meet the needs of the respective company, can be integrated into the existing structure with little effort. With compact and flexible data loggers such as the Loggito series, cost-effective networking of all measuring points is just as possible as low-channel data logging or the complex recording and monitoring of measurement data along an entire production line. With universal measurement inputs for many different sensor types, a high degree of flexibility and scalability through customized options and almost infinite expansion possibilities, the solutions from Delphin Technology enable the monitoring of decentralized, distributed production systems, mobile, location-independent access to all recorded parameters and, of course, ergonomic, user-oriented operability.

What are the advantages of remote monitoring and remote maintenance in industry?

Collecting and evaluating machine data from networked production enables companies to gain an insight into ongoing production in real time. Modern software solutions can be used to create individual dashboards on which all desired parameters - such as speeds, engine temperatures, pressures, oscillations, vibrations or coolant levels - can be displayed. Whether small or large amounts of data: Software such as ProfiSignal 20 from Delphin enables monitoring from any location - and completely platform-independent. The software takes over the visualization of the data fully automatically and brings together the most important data on a dashboard in a user-specific and individually adjustable way.

The advantages of the Remote monitoring for the industry:

- Global and real-time insights into ongoing production

- Monitoring the working area of a machine remotely

- Automated adaptation of production processes

- Centralized alarm management with a wide range of notification options

- Basis for further processes on the way to the smart factory, for example for condition monitoring or predictive maintenance

The advantages of the Remote maintenance for the industry:

- Saves expensive and time-consuming on-site visits by service technicians in many cases

- Enables rapid fault diagnosis by the manufacturer or technician via the Internet

- Updates, new machine cycles or control parameters can be loaded directly without the need for a lengthy interruption to production

Remote maintenance via WLAN

In existing systems where additional cables are not required or it is not possible to lay Ethernet cables, remote monitoring and maintenance must be ensured via WLAN. In this application, the right hardware is crucial for implementation. Data loggers and controllers from Delphin make it possible to link decentrally distributed measuring and control points via WLAN.

Remote monitoring and data security - do they go together?

Whether NC programs, production cycles or the chemical composition of products: In industry, internal company data is the key to success. Under no circumstances should sensitive company secrets be allowed to fall into the hands of third parties - which is why those responsible are so cautious when it comes to networking machines and systems with each other and, above all, with access to the internet. Industrial espionage, cybercrime or even just carelessness on the part of operating teams when handling internal data pose new challenges in the smart factory.

Delphin Technology relies on data encryption, such as SSL encryption for secure data transmission in combination with VPN tunnels, for significantly increased data security. In addition, further security mechanisms can be integrated into remote monitoring or remote maintenance. This prevents unauthorized remote control of systems in the event of a cyber attack, for example.

Test benches in the laboratory

High demands are placed on test benches in the laboratory. On the one hand, the devices used must be easy and intuitive to operate, while on the other, in many cases highly specialized measuring and testing tasks must be performed. Physical sensors must record temperatures, pressures, forces or torques in the laboratory and the measurement data obtained must be reliably stored in databases and visualized in a way that is accessible for evaluation. With hardware and software solutions specially adapted to the needs of modern laboratories, Delphin Technology is the competent partner for the chemical and pharmaceutical industries or universities. With preconfigured and mobile test systems and options for detailed implementation of verification and documentation obligations, Delphin solutions meet the increased regulatory requirements in the laboratory environment. The connection to higher-level systems such as LIMS or the easy connection of laboratory equipment from different manufacturers is realized through interfaces to Modbus, Profibus or SQL databases as well as the support of open standards such as OPC DA and UA. All Delphin systems can be customized for every task in the laboratory.

Secure remote monitoring and remote maintenance with OPC UA

Delphin Technology also relies on the modern, platform-neutral and secure OPC UA communication standard. OPC UA is regarded on the German and European market as a future-proof industrial protocol that works just as well on small controllers as it does on the largest enterprise servers, regardless of the transmission layer. OPC UA makes manufacturer-specific, proprietary protocols superfluous and enables fast data exchange in networks or application layers with a single protocol. IT security is specified as a separate security layer within the OPC UA standard. This allows company-specific rules and mechanisms to be defined for how devices, machines or services authenticate themselves or how data is encrypted. Secure sessions between an OPC UA client and the server or auditing services can also be implemented with the protocol.

Remote maintenance or remote monitoring in an industrial environment can be designed to be secure and protected. Simply contact us - we will be happy to advise you in a personal meeting about the options that Delphin Technology offers to ensure secure data exchange.

Is remote monitoring of sewage treatment plants, pumping stations or wind turbines possible?

With Delphin Technology solutions, the continuous monitoring of highly complex systems of all kinds can be realized. With centralized measurement data management, sewage treatment plants, pumping stations, wind turbines or offshore drilling rigs can of course also be reliably monitored. With complete solutions comprising hardware, software, engineering, commissioning and training from a single source and supported by customer-specific application developments, connection to higher-level systems such as LIMS, safety control technology and, of course, tamper-proof recording of measurement data, Delphin Technology is ideally prepared to meet the high demands of the chemical, pharmaceutical and energy technology sectors. The Delphin solutions offer numerous advantages:

- Fastest data acquisition even from many channels

- High-channel measurements of energy technology processes

- Versatile fieldbuses for simple connection to control systems

- Effective evaluation even of very long periods of time thanks to long-term stable databases

- Self-sufficient data storage for stand-alone operation

- Precise analyses of Sequence of Event sequences

- Access to data from anywhere in the world

Would you like to find out more about the possibilities of remote monitoring and remote maintenance in an industrial environment with Delphin Technology products or discuss a specific project with our experts? Then give us a call and arrange a personal consultation!

The right software for your measurement and testing solution

Data acquisition and analysis

With ProfiSignal Go you can display online data from the Message and Expert hardware in diagram form. Numerous analysis functions, such as zoom, cursor, movable axes, flags, ASCII export and calculation channels, enable fast display of measured values and post-processing.

To the product

Operating and monitoring

ProfiSignal Basic combines the functions of ProfiSignal Go with operating and monitoring elements of process visualisations, e.g. digital and analogue displays, switches, buttons and signal lamps. With Basic, you can create everything from simple visualisation diagrams to complex visualisation systems.

To the product

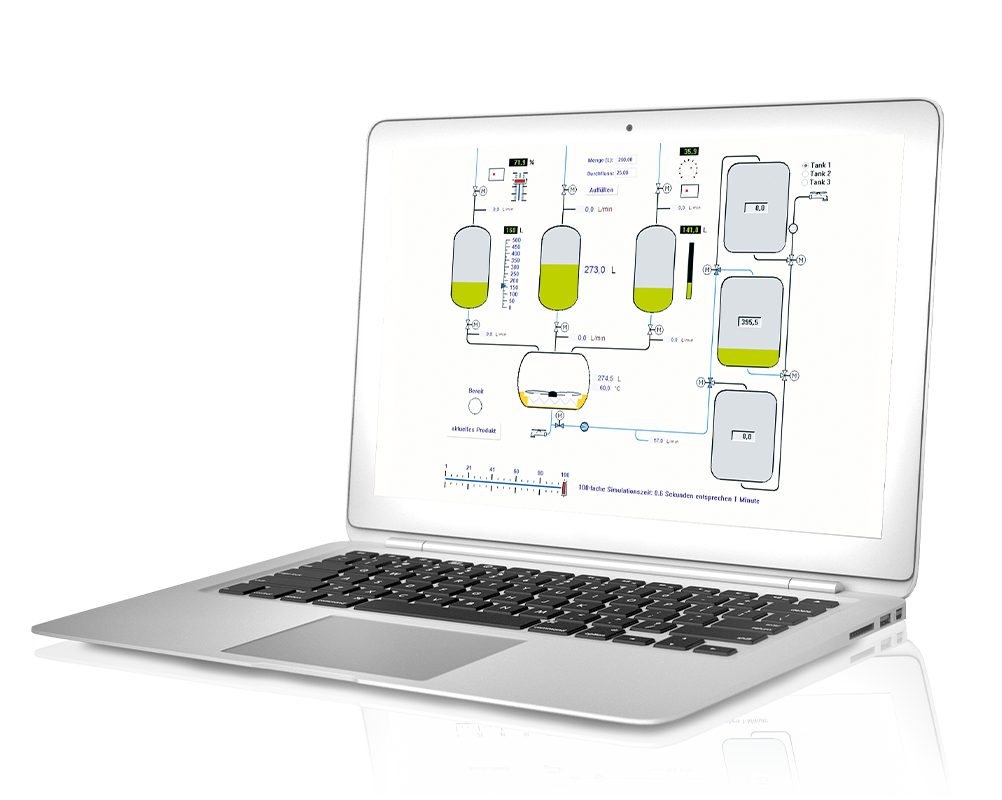

Automate and control

ProfiSignal Klicks supplements ProfiSignal Basic with functions for process automation. Structural diagrams for mapping the process as well as a script language (completely operable with the mouse) enable even the non-informatician to create complex test stand and automation applications with automatic report generation.

To the product

Visualisation and operation

With ProfiSignal 20 Basic you can create individual diagrams using a wide range of operating and monitoring elements. Both continuous processes (e.g. production data acquisition) and discontinuous measurement tasks (e.g. test measurements) can be visualised, operated and monitored without any programming effort. You can create the operating and monitoring diagrams by assembling and configuring the prefabricated elements.

To the product

Fast project planning and analysis of measurement data

With ProfiSignal 20 Go you can visualise your measurement data in just a few steps, both online and offline, in various diagram types, monitor, analyse, archive as a measurement file or export directly in the appropriate file format.

To the product

Central measurement data management

The Delphin Data Center is the solution used for the worldwide measurement networking and control of plants, machines and test stands.

To the product